Nov . 21, 2024 03:43 Back to list

high pressure hydraulic power unit factories

High Pressure Hydraulic Power Unit Factories A Modern Industrial Marvel

In the realm of industrial machinery, high pressure hydraulic power units (HPHPUs) play a crucial role in a myriad of applications ranging from manufacturing to construction. These units are designed to convert mechanical energy into hydraulic energy, allowing for efficient power transmission to various hydraulic systems. The factories dedicated to producing HPHPUs have evolved significantly, integrating advanced technologies and innovative practices that enhance performance and efficiency.

The Role of High Pressure Hydraulic Power Units

High pressure hydraulic power units are vital components in various sectors. They are used to operate hydraulic machinery such as presses, lifts, and excavation equipment. One of the core advantages of hydraulic systems is their ability to generate substantial force while maintaining compact sizes, enabling them to perform well in demanding environments. High pressure units, specifically, can produce pressures exceeding 5000 psi, making them indispensable in heavy-duty applications.

Manufacturing Processes in HPHPU Factories

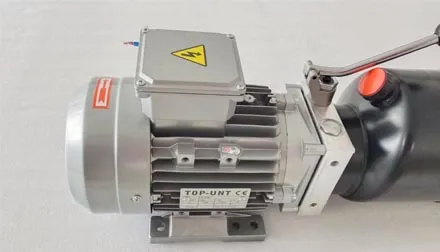

The manufacturing of high pressure hydraulic power units involves several intricate processes. Factories employ state-of-the-art machinery to mold, machine, and assemble individual components. Key components of a hydraulic power unit include pumps, motors, valves, and reservoirs. Each piece undergoes rigorous quality checks to ensure that it meets stringent industry standards.

The assembly line is typically automated, with robotics assisting in the precise placement and fastening of parts. This not only accelerates production times but also significantly reduces the margin of error, ensuring high quality in every unit produced. Moreover, some factories are incorporating 3D printing technology to create complex parts that were previously difficult to manufacture conventionally. This innovation allows for greater design flexibility and quicker prototyping.

Emphasis on Quality Control

Quality control is paramount in HPHPU manufacturing. Factories implement comprehensive testing protocols to ensure that every unit operates at optimal levels under high pressure. Units are subjected to performance tests, where they are evaluated for pressure tolerance, leakage, and overall functionality. Only those that successfully pass these tests are shipped to clients, providing a guarantee of reliability and efficiency.

high pressure hydraulic power unit factories

Moreover, many manufacturers are investing in research and development to enhance the performance of their hydraulic power units. This includes exploring new materials that can withstand higher pressures and improve durability while also being lighter in weight. As environmental concerns rise, some factories are also focusing on developing energy-efficient models that reduce hydraulic fluid consumption and minimize environmental impact.

The Global Market for HPHPUs

The demand for high pressure hydraulic power units is experiencing growth worldwide, driven by the expansion of industries such as construction, automotive, and manufacturing. Countries in Asia, particularly China and India, are seeing significant investments in infrastructure development, further fueling the need for efficient hydraulic solutions.

As a result, factories are increasingly not just serving local markets but are expanding their reach globally. Many seek to establish strategic partnerships and distribution networks that can effectively deliver their products on an international scale. This globalization has encouraged competition, leading to innovations in product design and functionality.

Future Trends and Innovations

Looking ahead, the future of high pressure hydraulic power unit factories seems promising. With advancements in technology, such as the Internet of Things (IoT) and artificial intelligence (AI), manufacturers are poised to enhance the functionality and efficiency of HPHPUs further. IoT can enable real-time monitoring of hydraulic systems, allowing for predictive maintenance and reducing downtime.

Furthermore, as sustainability becomes a major focus in industrial practices, factories will likely adopt more eco-friendly production techniques and materials. The evolution of HPHPUs will not only enhance their performance but will align with the global shift towards greener technologies.

Conclusion

High pressure hydraulic power unit factories are at the forefront of industrial innovation, supporting various sectors with their essential products. Through advanced manufacturing processes, stringent quality control, and a commitment to sustainability, these factories are well-positioned to meet the growing demands of a dynamic market. As technology continues to advance, the future of hydraulic power units promises to be more efficient, reliable, and environmentally friendly.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025