Jul . 28, 2024 16:35 Back to list

High-Quality 1 Ton Hydraulic Cylinder for Various Industrial Applications and Machinery Needs

Understanding the 1-Ton Hydraulic Cylinder A Powerful Tool in Modern Industries

Hydraulic cylinders are essential components in various industrial applications, providing the power and precision necessary for numerous tasks. Among them, the 1-ton hydraulic cylinder stands out due to its versatility and efficiency. This article explores the design, working principles, applications, and benefits of using a 1-ton hydraulic cylinder.

Design and Mechanism

A hydraulic cylinder operates based on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. A 1-ton hydraulic cylinder comprises several key parts a cylindrical barrel, a piston, and hydraulic fluid.

The barrel houses the piston, which moves back and forth as hydraulic fluid is pumped in and out. By controlling the fluid's pressure, operators can exert significant force using relatively small equipment. The 1-ton hydraulic cylinder is designed to lift or move loads weighing up to one ton, making it ideal for various lifting and pushing applications.

Working Principle

The functionality of a 1-ton hydraulic cylinder can be broken down into several steps

1. Fluid Inlet When hydraulic fluid is directed into the cylinder, it pushes the piston outward, generating force. 2. Force Generation The force exerted by the piston is calculated based on the pressure of the fluid and the area of the piston. For instance, if a hydraulic cylinder operates at 2,000 psi (pounds per square inch), a piston area of 6 square inches can lift approximately 1 ton.

3. Fluid Outlet Once the desired position is achieved, the fluid is released from the cylinder, allowing the load to remain in a lifted position until further action is needed.

This system allows for controlled and stable lifting, making the 1-ton hydraulic cylinder a preferred choice for many applications.

Applications

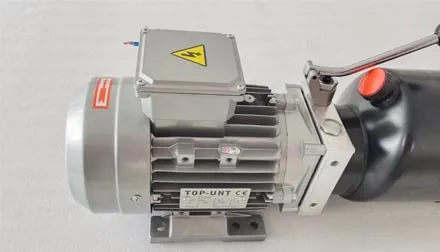

hydraulic cylinder 1 ton product

The 1-ton hydraulic cylinder is widely used across various industries, including

- Construction In construction sites, these cylinders assist in lifting heavy materials, such as steel beams and concrete blocks, making assembling structures much more efficient. - Automotive Repair Hydraulic cylinders are integral to vehicle repair shops, where they raise cars for maintenance tasks like oil changes or tire replacements. - Manufacturing Assembly lines use hydraulic cylinders to automate heavy lifting and positioning of parts, thereby increasing productivity and safety.

- Material Handling In warehouses and distribution centers, these cylinders are employed in forklifts and pallet jacks for moving heavy loads.

Advantages

The use of 1-ton hydraulic cylinders offers numerous advantages

- Power and Efficiency These cylinders can lift large weights with minimal effort, reducing the need for manual labor and increasing overall productivity.

- Precision Control Hydraulic systems allow for fine control over movements, making it easier to place loads accurately.

- Durability Hydraulic cylinders are built to withstand harsh conditions, ensuring a long operational life with minimal maintenance.

- Safety The stability of hydraulic lifting systems minimizes risks associated with heavy lifting, protecting both operators and materials.

Conclusion

The 1-ton hydraulic cylinder exemplifies the intersection of power and precision in modern industrial applications. Its ability to lift heavy loads with ease makes it an invaluable tool in construction, automotive, manufacturing, and material handling. As industries continue to evolve, the role of hydraulic systems, particularly 1-ton hydraulic cylinders, will undoubtedly expand, contributing to improved efficiency and safety in various work environments. Investing in quality hydraulic cylinders not only enhances operational capabilities but also promotes a safer and more productive workplace.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025