Aug . 13, 2024 14:54 Back to list

High-Performance Hydraulic Cylinder Manufacturing Facility Specializing in G-Force Applications and Innovations

Understanding G-Force Hydraulic Cylinder Manufacturing

In the world of industrial machinery and automation, hydraulic cylinders play a pivotal role in the development and operation of various systems. Among these, g-force hydraulic cylinders stand out due to their ability to withstand and function efficiently under extreme conditions. This article explores the significance of g-force hydraulic cylinder manufacturing, the key factors involved, and the advancements on the horizon.

Hydraulic cylinders operate on the principle of hydraulics, where fluid is used to generate force and motion. G-force hydraulic cylinders, specifically, are designed to handle and exert high pressures and forces, typically found in applications that require significant lifting power and durability. This includes industries such as aerospace, automotive, construction, and heavy equipment manufacturing.

Understanding G-Force Hydraulic Cylinder Manufacturing

Once the materials are selected, the next step involves machining. This process includes cutting, shaping, and assembling the various components of the hydraulic cylinder. Advanced CNC (Computer Numerical Control) technology is often employed to ensure that every part meets exact specifications. Precision is paramount, as even the smallest deviation can lead to leaks or failures under pressure.

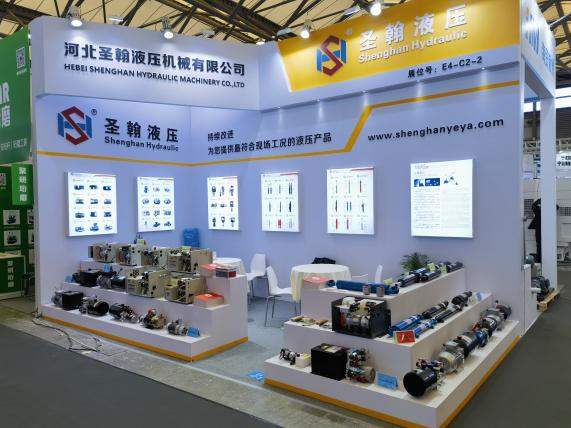

g force hydraulic cylinder factory

After machining, each cylinder undergoes rigorous testing. This includes pressure tests, leak tests, and performance evaluations to ensure that they can withstand g-forces and other extreme conditions without failing. Quality control is essential in this phase, as it guarantees that every produced cylinder meets industry standards and safety regulations.

An essential part of g-force hydraulic cylinder manufacturing is the integration of advanced technologies. Modern factories leverage automation, robotics, and IoT (Internet of Things) devices to enhance production efficiency and reduce human error. Automated systems can monitor the manufacturing process in real time, adjusting parameters as needed to maintain quality and productivity.

Sustainability is another increasingly important aspect of hydraulic cylinder manufacturing. As industries move toward greener practices, manufacturers are exploring ways to reduce waste and energy consumption. Innovations such as using eco-friendly hydraulic fluids and developing recyclable cylinder materials are gaining traction. This shift not only helps the environment but also appeals to consumers who prioritize sustainability in their purchasing decisions.

In conclusion, g-force hydraulic cylinder manufacturing is a complex yet fascinating field. It encompasses a blend of material science, engineering, and technology to produce components that are vital for various industries. As manufacturers continue to innovate and improve their processes, the future of g-force hydraulic cylinders looks promising. Advances in materials, automation, and sustainability will not only enhance the performance and reliability of these critical components but also contribute to a more efficient and eco-friendly industrial landscape.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025