Nov . 07, 2024 09:36 Back to list

Hydraulic Cylinder Grease Supplier for Enhanced Performance and Longevity

Understanding the Importance of Grease for Hydraulic Cylinder Manufacturers

Hydraulic cylinders play a crucial role in various industrial applications, offering powerful linear motion for heavy machinery. These components are central to the operation of equipment such as excavators, forklifts, and industrial presses, and their performance and longevity heavily depend on proper maintenance and lubrication. An integral part of this maintenance process is the use of grease, highlighting the essential role of grease manufacturers in the hydraulic cylinder industry.

The Role of Grease in Hydraulic Systems

Grease serves multiple purposes in hydraulic systems. Firstly, it acts as a lubricant, reducing friction between moving parts within the hydraulic cylinder. This reduction in friction not only enhances the efficiency of the hydraulic system but also protects the components from wear and tear, which can lead to costly repairs and downtime. Grease also plays a critical role in sealing, preventing contaminants such as dirt and moisture from entering the cylinder. This sealing effect is vital as contaminants can significantly decrease the efficiency of hydraulic systems and lead to failure.

The choice of grease is pivotal. Hydraulic cylinder manufacturers often specify particular types of grease that match the operational conditions and requirements of their equipment. Factors such as temperature range, pressure levels, and exposure to environmental conditions influence the type of grease selected. For instance, high-temperature applications may require synthetic greases that can withstand extreme conditions without breaking down. Conversely, applications exposed to wet environments may benefit from grease that possesses water-resistant properties.

Innovations in Grease Manufacturing

As industries evolve, so too does the demand for advanced lubrication solutions. Grease manufacturers are tasked with innovating their products to meet the changing needs of hydraulic cylinder manufacturers. This includes the development of bio-based and environmentally friendly greases that do not compromise performance. As sustainability becomes a focal point in manufacturing, biodegradable greases are gaining traction for their minimal environmental impact, offering a compelling alternative to traditional petroleum-based products.

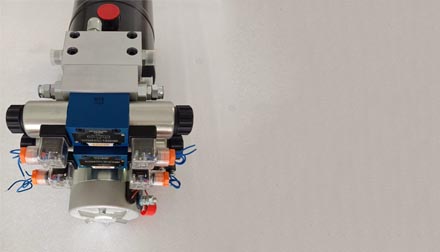

grease hydraulic cylinder manufacturer

Furthermore, the addition of additives in grease formulations is another area of innovation. These additives can enhance properties such as load-bearing capabilities, anti-wear characteristics, and oxidation stability. Advanced grease formulations also address specific challenges faced by hydraulic systems, such as extreme pressure and temperature fluctuations.

Working with Hydraulic Cylinder Manufacturers

Hydraulic cylinder manufacturers must collaborate closely with grease suppliers to ensure the right lubrication solutions are provided. This partnership is vital for developing specialized greases tailored to unique applications. By understanding the specific requirements of each hydraulic cylinder design, grease manufacturers can optimize their products for peak performance.

This collaboration can also lead to joint testing and validation of lubricant performance under various conditions. Hydraulic cylinder manufacturers benefit from testing grease in real-world scenarios, which enables them to make informed decisions about the lubrication solutions that best suit their products.

Conclusion

The relationship between grease manufacturers and hydraulic cylinder manufacturers is crucial for ensuring the reliability and efficiency of hydraulic systems. As technology advances and the industry evolves, so too must the solutions provided. Embracing innovation in grease formulations and focusing on sustainable practices will be essential for both industries. In doing so, they not only enhance their products' durability and performance but also contribute to a more sustainable future in manufacturing. Understanding the significance of grease in hydraulic applications prompts a greater appreciation for the manufacturers who specialize in producing these essential lubricants, ultimately helping to drive efficiency and productivity across various industrial sectors.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025