Nov . 10, 2024 07:03 Back to list

Hydraulic Cylinder Producer Specializing in Gland Wrench Solutions and Services

The Role of Gland Wrench Hydraulic Cylinder Manufacturers in Modern Industry

In today’s industrial landscape, the use of hydraulic cylinders is essential across a variety of applications, from manufacturing to construction. At the heart of these hydraulic systems lies one crucial component the gland wrench. As specialized tools used to tighten or loosen the gland nuts of hydraulic cylinders, gland wrenches serve an important function that is often overlooked. This article delves into the significance of gland wrench hydraulic cylinder manufacturers and their impact on the industry.

Understanding Hydraulic Cylinders

Hydraulic cylinders are mechanical devices that convert hydraulic energy into linear motion. They are widely used to lift heavy loads and perform tasks that require significant force, making them integral to equipment such as excavators, forklifts, and other heavy machinery. The efficient operation of these cylinders depends heavily on their maintenance and the quality of their components, including the gland nut.

The gland nut is a key component in hydraulic cylinders because it houses the seals that prevent hydraulic fluid from escaping. Over time, the seals can wear out and the connection can loosen—an issue that can lead to hydraulic fluid leakage and reduced efficiency. This is where gland wrenches come into play, ensuring that gland nuts are properly tightened and that seals remain effective.

The Importance of Gland Wrench Manufacturers

Manufacturers of gland wrenches play a critical role in maintaining the integrity and performance of hydraulic cylinders. These companies specialize in designing and producing high-quality gland wrenches tailored to the specifications of various hydraulic cylinder types. The expertise of these manufacturers ensures that their products meet industry standards and provide the durability and reliability essential for heavy-duty applications.

One of the most significant advantages of working with specialized gland wrench manufacturers is their ability to create custom solutions. Different hydraulic systems can vary greatly in size and design, and a one-size-fits-all approach often leads to inefficiencies. Custom gland wrenches designed specifically for a particular hydraulic application can greatly enhance the ease of maintenance and extend the lifespan of the hydraulic cylinder.

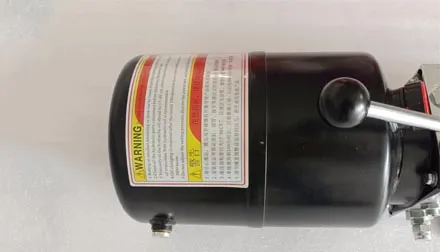

gland wrench hydraulic cylinder manufacturer

Innovation in Gland Wrench Design

As industries evolve, so do the tools that support them. Gland wrench manufacturers are continuously innovating their designs to improve efficiency and usability. Advanced materials that are both lightweight and strong are being introduced, reducing user fatigue while enhancing durability. Furthermore, ergonomic designs that fit comfortably in hand help reduce the risk of injuries during use.

Additionally, some manufacturers are integrating technology into their products. For instance, electronic torque wrenches can provide precise measurements during tightening, ensuring that gland nuts are secured to the exact specifications required. This level of precision minimizes the risk of over-tightening or under-tightening, both of which can lead to significant operational issues down the line.

The Future of Gland Wrench Hydraulic Cylinder Manufacturing

As industries progress toward more sustainable practices and seek improved efficiency, gland wrench manufacturers are also exploring environmentally friendly materials and production processes. This shift not only caters to the increasing demand for sustainable products but also opens up new markets and opportunities for growth.

Moreover, the rise of automation and smart technology in manufacturing can lead to new designs and manufacturing processes for gland wrenches. The integration of sensors and IoT technology could enable real-time monitoring of hydraulic systems, allowing for proactive maintenance and reducing the likelihood of failure.

Conclusion

Gland wrench hydraulic cylinder manufacturers play a pivotal role in modern industry, supporting the maintenance and efficiency of hydraulic systems across various sectors. Their commitment to innovation, customization, and quality assurance underpins the reliability of hydraulic cylinders, ensuring that vital machinery can operate smoothly and safely. As industries continue to evolve and embrace new technologies, these manufacturers will remain at the forefront, adapting to meet the changing needs of the market and contributing to the overall advancement of hydraulic engineering.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 - Hebei Shenghan Hydraulic Machinery Co., Ltd.|Precision Engineering&Customizable Hydraulic Components

NewsSep.01,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 - Hebei Shenghan

NewsSep.01,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Customization, Chrome-Plated Piston Rod, Indel Seals

NewsSep.01,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan|Customizable Hydraulic Cylinder&Durable Oil Cylinder

NewsSep.01,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan

NewsSep.01,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsSep.01,2025