Nov . 27, 2024 22:49 Back to list

Manufacturing Gland Seals for Hydraulic Cylinders in Industrial Production Facilities

Understanding Gland Seals in Hydraulic Cylinders Function, Design, and Manufacturing

In the realm of hydraulic systems, gland seals play a pivotal role in ensuring the efficient operation of hydraulic cylinders. These crucial components are designed to prevent fluid leakage, maintain pressure, and enhance the overall performance of the hydraulic system. This article will explore the function, design considerations, and manufacturing processes of gland seals used in hydraulic cylinders.

What is a Gland Seal?

A gland seal is an essential sealing element located at the end of a hydraulic cylinder where the piston rod exits. The primary function of a gland seal is to accommodate the movement of the piston rod while preventing hydraulic fluid from escaping the cylinder. This ensures that the system operates efficiently, providing the necessary force without loss of fluid or pressure.

The Function of Gland Seals

Gland seals serve several critical functions in hydraulic cylinders, including

1. Fluid Containment The primary role of the gland seal is to contain the hydraulic fluid within the cylinder. By providing a tight seal, it prevents the fluid from leaking out, which is vital for maintaining pressure and ensuring optimal performance.

2. Rod Protection Gland seals not only prevent fluid leakage but also protect the piston rod from external contaminants such as dust, dirt, and moisture. This protection is essential for prolonging the life of the hydraulic system and ensuring reliable operation.

3. Compensating for Wear Over time, seals can wear due to the constant movement and pressure changes within the hydraulic system. Gland seals are typically designed to accommodate this wear, allowing for a longer operational life.

Design Considerations

When designing gland seals for hydraulic cylinders, several factors must be taken into account

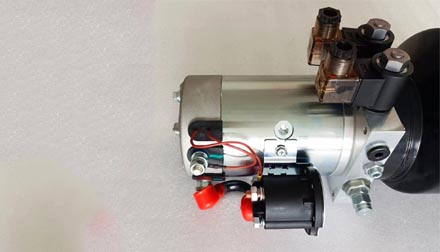

gland seal in hydraulic cylinder factory

1. Material Selection Gland seals can be made from various materials, including rubber, polyurethane, and PTFE, each offering different properties in terms of wear resistance, temperature tolerance, and chemical compatibility. The choice of material depends on the specific application and environmental conditions the seals will face.

2. Seal Geometry The shape and size of the gland seal are critical for its performance. The design must balance the need for a tight seal with the ability to allow smooth movement of the piston rod. Engineers often rely on specialized software to simulate seal performance and optimize geometry for specific applications.

3. Pressure and Temperature Ratings Gland seals are subjected to varying pressures and temperatures depending on the application. It is essential for manufacturers to evaluate the expected operating conditions to ensure the selected seal can withstand the stresses without failure.

Manufacturing Process

The manufacturing of gland seals involves several key steps

1. Material Preparation The chosen materials are prepared and formulated to create the desired properties for the gland seal. This may involve mixing compounds to achieve specific hardness, flexibility, and durability.

2. Molding The prepared material is then molded into the specific shape of the gland seal. Various molding techniques, such as compression molding or injection molding, can be used, depending on the design and production scale.

3. Quality Control After molding, gland seals undergo rigorous quality control measures to ensure they meet the necessary specifications. This includes dimensional checks, pressure testing, and performance assessments to guarantee reliability in the final application.

4. Finishing and Packaging Once quality checks are complete, gland seals may be subjected to finishing processes, such as trimming and surface treatment, before being packaged for shipment to customers.

Conclusion

Gland seals are critical components in the functionality of hydraulic cylinders, playing a vital role in fluid containment, rod protection, and wear compensation. Understanding their design considerations and manufacturing processes is essential for engineers and manufacturers involved in hydraulic systems. By prioritizing quality in both design and production, the hydraulic industry can ensure the reliability and efficiency of its products, ultimately leading to improved performance and longevity of hydraulic equipment. As technology advances, the development of more innovative and effective gland seals will continue to enhance the capabilities of hydraulic systems across various applications.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025