Nov . 19, 2024 06:00 Back to list

Gas Hydraulic Cylinder Manufacturers and Their Innovative Solutions for Industrial Applications

The Evolution and Impact of Gas Hydraulic Cylinder Factories

In recent years, gas hydraulic cylinders have gained significant traction in various industries, thanks to their versatility, efficiency, and compact design. These cylinders harness the power of gases to create hydraulic pressure, providing an effective solution for lifting, pushing, and pulling heavy loads. This technology is not just a marvel of engineering; it is a product of specialized factories dedicated to innovation and quality manufacturing.

Gas hydraulic cylinder factories play a crucial role in the production process, ensuring that every cylinder meets strict quality and safety standards. The manufacturing process begins with the careful selection of materials that can withstand high pressures and extreme conditions. Steel, aluminum, and composite materials are commonly used, as they provide the strength and durability necessary for effective operation. Advanced machining techniques are employed to create precision components, which are then assembled using state-of-the-art technology.

One of the key advantages of gas hydraulic cylinders is their ability to operate in confined spaces where traditional hydraulic systems may fail. Factories leverage this unique feature to design cylinders that are not only powerful but also compact and lightweight. This adaptability opens up new opportunities across sectors such as construction, automotive, and manufacturing, where space and efficiency are paramount.

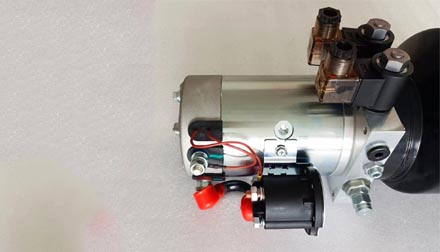

gas hydraulic cylinder factories

Furthermore, gas hydraulic cylinder factories are increasingly incorporating automation and robotics into their production lines. This technological advancement enhances precision while reducing human error. By employing computer numerical control (CNC) machines and automated assembly lines, these factories can produce cylinders at a faster rate, ultimately lowering costs and meeting growing market demands. The push towards automation also reflects a broader trend across industries aimed at improving productivity and maintaining a competitive edge.

Sustainability is becoming an essential focus in the manufacturing landscape, and gas hydraulic cylinder factories are no exception. Many companies are investing in environmentally friendly practices, such as recycling materials and utilizing energy-efficient machinery. By prioritizing sustainability, these factories not only reduce their carbon footprint but also appeal to an increasingly eco-conscious market.

In conclusion, gas hydraulic cylinder factories are at the forefront of engineering innovation, playing a significant role in developing efficient and powerful machinery for various applications. As these factories continue to evolve, incorporating advanced technology and sustainable practices, they are poised to meet the demands of an ever-changing industrial landscape. The future of gas hydraulic cylinders looks promising, offering exciting possibilities for enhanced performance and efficiency across multiple sectors. This industry not only exemplifies modern manufacturing prowess but also sets the stage for future advancements in hydraulic technology.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025