Nov . 03, 2024 16:01 Back to list

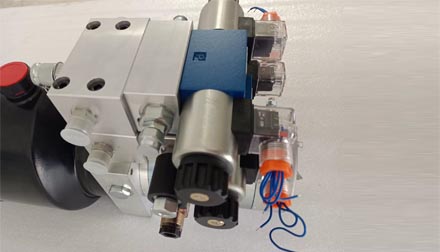

foot pump hydraulic cylinder products

Hydraulic Cylinders and Foot Pump Systems An Essential Guide

Hydraulic systems are integral to various mechanical and industrial applications, and among the most convenient methods to operate them is through the use of a foot pump hydraulic cylinder. This device plays a crucial role in lifting, pushing, or pulling heavy loads with ease, making it a favorite choice for mechanics, construction workers, and DIY enthusiasts alike.

At its core, a hydraulic cylinder is a mechanical device that uses the hydraulic power generated by a pressurized fluid to create linear motion. When paired with a foot pump, it offers an efficient, hands-free solution for controlling the hydraulic fluid, thereby allowing users to apply force without the need for manual effort or electrical power. The foot-operated pump strikes the perfect balance between convenience and effectiveness, showcasing the brilliance of hydraulic engineering.

One of the key advantages of utilizing a foot pump hydraulic cylinder is its portability. Many models are designed to be lightweight and compact, making them easy to transport to various work sites. This feature is particularly beneficial for mobile mechanics or contractors who often work in different locations. Besides, the simplicity of the foot pump mechanism requires minimal setup, allowing users to quickly get to work.

foot pump hydraulic cylinder products

Foot pump hydraulic cylinders are often available in various capacities, allowing for operations from lighter tasks like lifting automotive components to more heavy-duty applications such as elevating construction machinery. Manufacturers produce these cylinders with various materials, often ensuring durability and longevity in harsh working conditions. The choice of materials often influences not just the weight and resilience of the cylinder, but also its resistance to potential hazards, like corrosion from exposure to chemicals or moisture.

Another factor to consider is the safety features integrated into these devices. Many foot pump hydraulic cylinders come equipped with built-in safety valves that prevent over-pressurization, ensuring the system operates within safe limits. Users can therefore have peace of mind, knowing that their equipment is designed with safety as a priority.

Despite the robust capabilities, using a foot pump hydraulic cylinder requires some understanding of hydraulic principles and safety protocols. The operator must be aware of the cylinder's load capacity and ensure not to exceed it. Proper maintenance, such as checking for leaks and ensuring the pump and cylinder are adequately lubricated, will also extend the lifespan of the equipment.

In conclusion, foot pump hydraulic cylinders are invaluable tools that marry efficiency with simplicity. Their ability to provide significant force with minimum physical exertion makes them indispensable in various sectors. Whether you are looking to elevate heavy materials in a workshop or operate machinery on a construction site, investing in a quality foot pump hydraulic cylinder is a wise choice. With proper use and maintenance, these devices can enhance productivity while ensuring safety, making them a cornerstone of modern hydraulic systems.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025