Dec . 03, 2024 18:02 Back to list

Exploring Flowfit Hydraulic Double Acting Cylinders for Enhanced Performance and Efficiency

Understanding Flowfit Hydraulic Double Acting Cylinders A Comprehensive Overview

In the realm of hydraulic systems, the choice of components plays a pivotal role in ensuring efficiency and performance. Among these components, hydraulic cylinders stand out as critical elements, particularly double acting cylinders. Flowfit has emerged as a reputable name in the industry, offering a variety of hydraulic double acting cylinder products that are engineered for durability and efficiency. This article delves into the features, benefits, applications, and general maintenance of Flowfit hydraulic double acting cylinders.

What Are Double Acting Cylinders?

A double acting hydraulic cylinder is a device that utilizes hydraulic pressure to perform work in both directions of operation. It has two ports, one for extending the cylinder and another for retracting it. This mechanism allows for greater control and efficiency compared to single acting cylinders, which only utilize hydraulic power in one direction.

Flowfit's hydraulic double acting cylinders are designed to convert hydraulic energy into mechanical energy, providing a reliable source of linear force. This is achieved through the use of hydraulic fluid, typically oil, which is pumped into either side of the cylinder, causing the piston to move.

Features of Flowfit Hydraulic Double Acting Cylinders

Flowfit's double acting cylinders are characterized by their robust construction and advanced engineering. Some of their key features include

1. High-Quality Materials These cylinders are constructed from high-strength materials that can withstand heavy loads and extreme working conditions. They are often made of treated steel or aluminum, both of which offer excellent resistance to wear and corrosion.

2. Sealing Technology Flowfit employs state-of-the-art sealing technologies that prevent leaks and ensure longevity. High-quality seals minimize the loss of hydraulic fluid and thereby maintain system pressure.

3. Customization Options Flowfit provides a variety of customization options, allowing customers to select the size, stroke length, and mounting styles that best suit their specific application needs.

4. Efficiency and Precision The design of these cylinders supports smooth and precise linear motion, making them ideal for applications requiring accuracy and repeatability.

Benefits of Using Flowfit Hydraulic Double Acting Cylinders

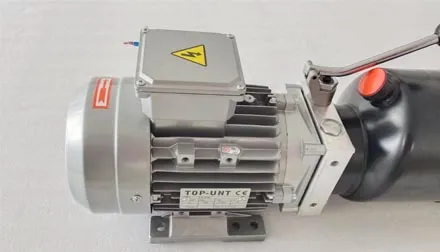

flowfit hydraulic double acting cylinder products

1. Increased Power Output The ability to apply force in both directions makes double acting cylinders far more efficient, allowing them to handle heavier loads with ease.

2. Reduced Cycle Times Hydraulic double acting cylinders can perform work faster than single acting cylinders, thereby improving the overall efficiency of hydraulic systems.

3. Versatile Applications Their design and functionality make them suitable for a diverse range of applications, from agriculture and construction to manufacturing and material handling.

4. Cost-Effectiveness By utilizing high-quality materials and components, Flowfit's hydraulic cylinders often require less frequent maintenance and replacement, leading to long-term savings.

Applications of Flowfit Hydraulic Double Acting Cylinders

Flowfit hydraulic double acting cylinders find uses in numerous industries, including

- Construction They are vital in heavy machinery for tasks such as lifting, pushing, and pulling. - Agriculture Used in equipment like tractors and harvesters for various lifting and towing applications. - Manufacturing Essential in assembly lines, robotics, and material handling systems for controlled movement. - Transportation Employed in trailers and trucks for loading and unloading cargo.

Maintenance Tips for Hydraulic Double Acting Cylinders

To ensure the longevity and efficiency of Flowfit hydraulic double acting cylinders, regular maintenance is crucial. Some maintenance tips include

1. Regular Inspections Routinely check for leaks, wear, or damage on seals and connections. 2. Fluid Checks Maintain proper hydraulic fluid levels and ensure the fluid is in good condition to prevent contamination. 3. Cleaning Keep the exterior of the cylinder clean and free from debris, which can cause wear over time.

4. Consult the Manufacturer Always refer to the manufacturer’s guidelines for specific maintenance protocols and service intervals.

In conclusion, Flowfit hydraulic double acting cylinders represent a robust and efficient solution for a variety of applications. With their advanced features, efficient design, and high-quality construction, these cylinders continue to be a reliable choice in the industry, ensuring precise operation and enhanced productivity across numerous sectors.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025