Aug . 12, 2024 06:16 Back to list

Exploring the Production Processes of Hydraulic Lift Power Unit Manufacturing Companies Worldwide

Hydraulic Lift Power Unit Factories A Comprehensive Overview

Hydraulic lift power units are crucial components in various industrial applications, enabling the lifting and lowering of heavy loads with remarkable efficiency. These systems utilize the principles of hydraulics to transmit power through fluid, making them indispensable in construction, manufacturing, and transportation industries. This article delves into the importance of hydraulic lift power unit factories, the manufacturing processes involved, and the future trends shaping the industry.

Importance of Hydraulic Lift Power Units

Hydraulic power units (HPUs) serve as the heart of hydraulic systems, providing the necessary pressure and flow required for operation. Applications range from car lifts in service stations to heavy machinery in warehouses and construction sites. Their importance cannot be overstated, as they enhance productivity and safety by allowing workers to handle heavy items with precision and minimal physical effort.

Hydraulic lift systems are preferred over mechanical systems in many scenarios due to their ability to lift heavier loads with ease and their compact design. The adaptability of these systems allows for customized solutions tailored to specific operational needs, enabling businesses to optimize their workflows.

Manufacturing Processes in HPU Factories

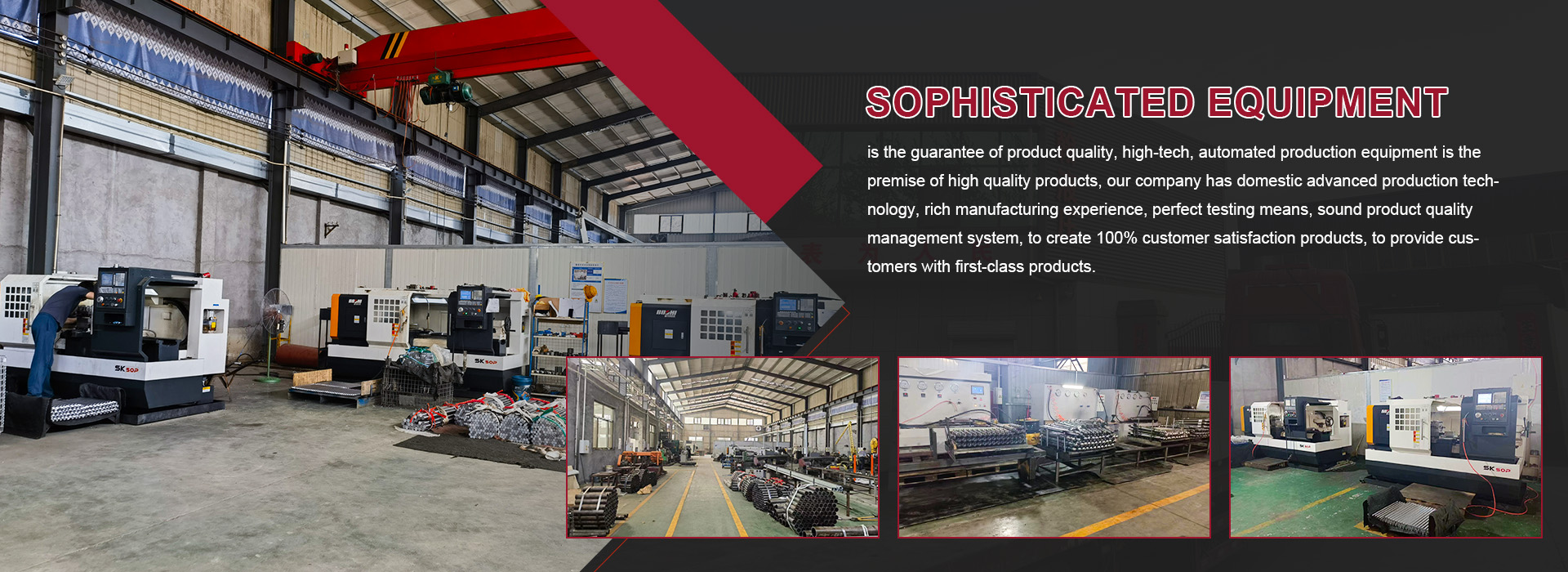

The manufacturing of hydraulic lift power units involves a series of precise and technologically advanced processes. Factories that produce these units typically follow several key stages

1. Design and Engineering The process begins with design engineers who create blueprints for the hydraulic systems based on specific client requirements. Computer-aided design (CAD) software is often employed to ensure accuracy and efficiency.

2. Material Selection Durable materials, such as steel and high-grade alloys, are selected for their strength and resistance to pressure. Quality control measures are vital during this stage to ensure that all materials meet the required standards.

3. Component Fabrication The individual components of the HPU, such as pumps, cylinders, valves, and reservoirs, are manufactured. This may involve machining processes like cutting, milling, and welding to achieve the desired specifications.

hydraulic lift power unit factories

4. Assembly Once fabricated, the components undergo a meticulous assembly process. Skilled technicians ensure that all parts fit together perfectly, ensuring functionality and safety.

5. Testing Before reaching the market, each hydraulic lift power unit undergoes rigorous testing. This includes pressure testing, flow rate assessments, and operational testing to ensure that the unit meets industry standards and client specifications.

6. Quality Control Quality assurance is an ongoing process within HPU factories. Regular inspections and monitoring during and after production ensure that each unit is built to last and operate effectively.

Future Trends in Hydraulic Lift Power Unit Production

The hydraulic industry is evolving, with innovations shaping the future of HPU manufacturing. Key trends include

- Integration of IoT Technology The Internet of Things (IoT) is making its way into hydraulic systems, allowing for real-time monitoring and data analysis. This enables predictive maintenance, reducing downtime and operational costs.

- Sustainability Initiatives As industries seek to reduce their carbon footprints, hydraulic lift power unit factories are adopting more sustainable practices. This includes the development of eco-friendly hydraulic fluids and energy-efficient manufacturing processes.

- Advancements in Automation Automation is revolutionizing the manufacturing process, increasing efficiency, and reducing human error. Robotic systems are increasingly used for assembly and quality control, streamlining production lines.

In conclusion, hydraulic lift power unit factories play a pivotal role in modern industry by providing essential equipment that enhances efficiency and safety. As technology continues to advance, these factories will adapt and innovate, ensuring that they remain at the forefront of hydraulic system manufacturing. The future holds great promise for this vital sector, with advancements that will further optimize production processes and improve product reliability.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025