Jul . 27, 2024 18:14 Back to list

Exploring Manufacturers of Dual Piston Hydraulic Cylinders for Enhanced Industrial Performance

The Importance of Dual Piston Hydraulic Cylinders in Modern Industry

In the realm of industrial machinery and engineering, the hydraulic cylinder plays a pivotal role, particularly the dual piston hydraulic cylinder. These sophisticated units are integral to a broad range of applications, from manufacturing and construction to automotive technologies. The dual piston hydraulic cylinder offers distinct advantages in terms of performance, efficiency, and reliability that make it a preferred choice for many factories.

Understanding Dual Piston Hydraulic Cylinders

A dual piston hydraulic cylinder is a type of actuator that uses two pistons to generate linear motion. This configuration allows for greater force output and improved responsiveness compared to single piston systems. The dual pistons operate within a cylindrical housing filled with hydraulic fluid, which facilitates the transfer of energy. By controlling the flow of this fluid, operators can precisely manipulate the movement and speed of the pistons, enabling efficient operation of various machines.

Benefits of Dual Piston Hydraulic Cylinders

1. Enhanced Force Application One of the primary advantages of dual piston hydraulic cylinders is their ability to produce higher force levels. This is particularly beneficial in heavy-duty applications, such as in construction equipment or presses used in manufacturing. With the capacity to lift and move heavy loads, dual piston systems enhance productivity and reduce operational time.

2. Improved Stability and Control The design of dual piston cylinders allows for better load distribution, leading to increased stability during operation. This enhanced stability is critical in applications where precision is paramount, such as in the production of automotive parts or in assembly lines. The control over the hydraulic fluid flow also allows operators to fine-tune movements, thereby minimizing errors and improving accuracy.

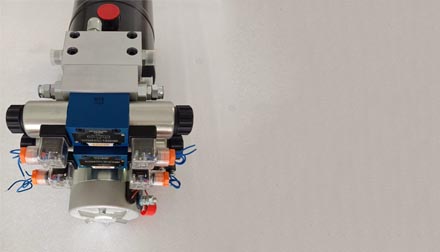

dual piston hydraulic cylinder factories

3. Versatility Dual piston hydraulic cylinders are highly versatile and can be customized to meet specific operational requirements. They can be designed to operate in various environments and can be adapted for different mounting styles, making them suitable for a wide range of industrial machinery.

4. Reduced Wear and Tear The efficient operation of dual piston cylinders results in less stress and wear on components, leading to longer operational life and reduced maintenance needs. This durability not only saves time and resources but also contributes to lower overall operational costs, making them an economically wise choice for manufacturers.

Applications of Dual Piston Hydraulic Cylinders

Due to their numerous advantages, dual piston hydraulic cylinders are employed across various sectors. In construction, these cylinders are used in excavators and loaders, significantly enhancing their lifting capabilities and functionality. In manufacturing, they are employed in hydraulic presses for metal forming, where precise force application is critical. The automotive industry also benefits from dual piston cylinders in assembly lines, where they streamline processes and improve overall efficiency.

The Role of Factories Producing Dual Piston Hydraulic Cylinders

The factories that specialize in manufacturing dual piston hydraulic cylinders are crucial to the continuity of these industries. They combine advanced engineering practices, high-quality materials, and cutting-edge technology to produce reliable and efficient hydraulic systems. These manufacturers focus on quality control and innovation, ensuring that their products meet the rigorous demands of modern industrial applications.

In conclusion, dual piston hydraulic cylinders represent a vital component in today’s industrial landscape. Their superior force application, stability, versatility, and durability make them indispensable in various sectors. As industries continue to advance and seek more efficient solutions, the importance of quality manufacturers producing dual piston hydraulic cylinders cannot be overstated. The future of industrial operations will undoubtedly be shaped by the continued evolution and refinement of these powerful hydraulic systems.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025