Aug . 13, 2024 06:26 Back to list

Exploring a Variety of Hydraulic Cylinder Pins for Enhanced Performance and Reliability in Machinery

Understanding Hydraulic Cylinder Pins Essential Components for Efficiency

Hydraulic systems are a marvel of engineering, used across various industries, from construction machinery to automotive applications. At the heart of these systems lies a critical component known as hydraulic cylinder pins. These pins play a crucial role in the functionality and efficiency of hydraulic cylinders, which are integral to transforming hydraulic energy into mechanical work. In this article, we will explore the characteristics, applications, and importance of hydraulic cylinder pins in ensuring seamless operation.

What are Hydraulic Cylinder Pins?

Hydraulic cylinder pins are specialized fasteners used to connect and secure hydraulic cylinders to other components within a hydraulic system. They are typically made from high-strength materials such as steel or aluminum, designed to withstand high loads, pressure, and the harsh conditions typical in industrial environments. These pins can vary in size, shape, and design depending on the specific application requirements, but their primary function remains the same—providing stable, reliable connections.

Characteristics and Specifications

When choosing hydraulic cylinder pins, several key specifications need to be considered

1. Material Strength The pins must exhibit high tensile strength to resist bending or breaking under load. Common materials include stainless steel and alloy steel, which offer robustness and resistance to corrosion.

2. Dimensions The diameter and length of the pins must be compatible with the hydraulic cylinder and associated components. Precision engineering ensures that the pins fit snugly without excessive play, which could lead to wear and failure.

3. Coating and Finish To enhance resistance to corrosion and wear, hydraulic cylinder pins may feature surface treatments, such as plating or anodizing. This is especially important in environments exposed to moisture or harsh chemicals.

4. Load Capacity It is crucial to select pins with appropriate load-bearing capacities based on the hydraulic system's operating conditions. Underestimating loads can lead to catastrophic failures.

Applications of Hydraulic Cylinder Pins

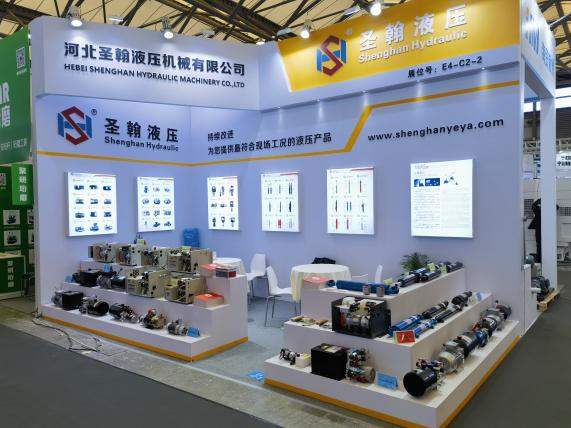

hydraulic cylinder pins products

Hydraulic cylinder pins are ubiquitous across various industries. Their applications include

- Construction Equipment Heavy machinery such as excavators and bulldozers rely on hydraulic cylinders for movement and stability. Hydraulic cylinder pins are essential for connecting the hydraulic cylinders to the machinery itself, enabling various functions like lifting and digging.

- Automotive Industry In automotive repair and manufacturing, hydraulic cylinders are used in lifts and presses. Pins are critical for ensuring the secure attachment of hydraulic cylinders, allowing for the safe lifting of vehicles during maintenance.

- Manufacturing Machinery Many manufacturing processes utilize hydraulic systems for press machines and robotic arms, where precision and strength are vital. Hydraulic pins ensure that components remain securely attached, maintaining operational integrity.

- Aerospace and Marine Applications In aviation and marine engineering, where safety is paramount, hydraulic cylinder pins are essential components that contribute to the reliability and efficiency of systems such as landing gear and steering mechanisms.

Importance of Quality and Maintenance

The quality of hydraulic cylinder pins cannot be overstated. Poor-quality pins can lead to system failures, resulting in downtime and costly repairs. Therefore, it is crucial to source these components from reputable manufacturers who adhere to stringent quality standards.

Regular maintenance and inspections of hydraulic cylinder pins are also essential. Ensuring that the pins are free from wear, corrosion, and damage can prevent unexpected failures and enhance the overall lifespan of hydraulic systems.

Conclusion

Hydraulic cylinder pins may seem like small components, but they play a significant role in the effectiveness of hydraulic systems across various industries. By understanding their characteristics, applications, and importance, engineers and operators can make informed decisions that enhance the safety and efficiency of their hydraulic systems. Investing in high-quality hydraulic cylinder pins and maintaining them effectively will lead to improved operational performance and reliability, demonstrating that sometimes, the smallest parts can make the most significant impact.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025