Nov . 02, 2024 12:42 Back to list

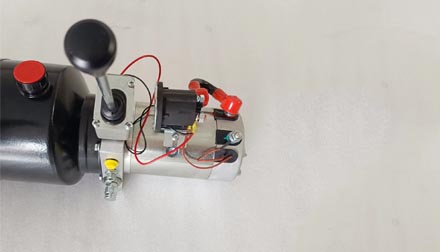

electric over hydraulic cylinder product

Electric Over Hydraulic Cylinders A Modern Solution for Heavy Machinery

In the realm of industrial machinery and automation, the demand for efficient power systems has led to the innovative development of electric over hydraulic cylinders. This technology combines the precision of electric control with the incredible force generation capabilities of hydraulic systems. As industries seek to maximize productivity while minimizing energy consumption, electric over hydraulic cylinders have emerged as a transformative solution, revolutionizing the way heavy machinery operates.

What are Electric Over Hydraulic Cylinders?

Electric over hydraulic cylinders streamline the operation of hydraulic systems by integrating electric drives and control mechanisms. Unlike traditional hydraulic systems, which rely solely on hydraulic fluid pressure for actuation, electric over hydraulic systems utilize electric motors to drive hydraulic pumps. This dual approach allows for more precise control, better energy efficiency, and improved responsiveness.

At the heart of this technology is the hydraulic cylinder, a component designed to convert hydraulic energy into linear motion. Electric over hydraulic cylinders come equipped with sensors and advanced control systems that can instantaneously adjust the flow and pressure of the hydraulic fluid. This means that operators can achieve fine-tuned movements that are essential for applications requiring high precision.

Advantages of Electric Over Hydraulic Cylinders

1. Energy Efficiency One of the most significant benefits of electric over hydraulic cylinders is their energy efficiency. Traditional hydraulic systems often operate continuously, wasting power even when not actively in use. In contrast, electric over hydraulic systems can be programmed to operate on demand, resulting in lower energy consumption and reduced operational costs.

2. Precision Control The advanced control systems in electric over hydraulic cylinders enable high levels of accuracy. Operators can precisely control the speed, position, and force of the cylinder's movement, making them ideal for applications that require meticulous handling, such as in manufacturing lines or robotic applications.

electric over hydraulic cylinder product

3. Reduced Maintenance Hydraulic systems traditionally have a reputation for requiring frequent maintenance due to the potential for leaks and other mechanical failures. The electric drive system reduces the number of hydraulic components required, leading to lower maintenance needs and longer system life.

4. Enhanced Safety Incorporating electric controls can enhance safety in machinery operations. Electric over hydraulic systems can include features such as overload protection, positional feedback systems, and emergency shutoff functions, which help prevent accidents and ensure user safety.

5. Smart Integration With the rise of Industry 4.0, electric over hydraulic cylinders can be easily integrated into smart manufacturing systems. Their compatibility with IoT devices allows for real-time monitoring and data collection, enabling predictive maintenance and further optimizing operational efficiency.

Applications in Various Industries

Electric over hydraulic cylinders find applications across a wide array of industries, including automotive, aerospace, construction, and manufacturing. In the automotive sector, for instance, they are utilized for tasks such as component assembly and quality control. In construction, these cylinders power equipment like excavators and cranes, aiding in tasks that require significant lifting capacity and precision.

Conclusion

As the industrial landscape continues to evolve towards greater automation and efficiency, electric over hydraulic cylinders stand out as a key technology facilitating this shift. Their combination of energy efficiency, operational precision, and reduced maintenance requirements positions them as a preferred choice for modern manufacturers and operators. By investing in electric over hydraulic solutions, industries can enhance productivity while aligning with sustainability goals, marking a definitive step towards the future of heavy machinery.

-

China Carbon Fiber Hydraulic Cylinder Light & Durable

NewsJun.05,2025

-

Premium T5 Hydraulic Slave Cylinder Factories Quality Production

NewsJun.05,2025

-

Wingspan Power Unit Company Efficient Power Solutions for Industry

NewsJun.04,2025

-

High-Performance Wingspan Power Unit Products Energy Solutions

NewsJun.04,2025

-

Premium Curved Hydraulic Cylinders Durability & Precision

NewsJun.04,2025

-

Heavy-Duty 3x8 Hydraulic Cylinder Premium Industrial Solution

NewsJun.04,2025