Nov . 16, 2024 09:57 Back to list

dual stage hydraulic cylinder manufacturers

Understanding Dual Stage Hydraulic Cylinder Manufacturers A Comprehensive Overview

In the realm of hydraulic systems, dual stage hydraulic cylinders stand out for their capability to enhance efficiency and power. As industries increasingly rely on complex mechanisms to improve productivity, understanding the role of dual stage hydraulic cylinder manufacturers becomes imperative. This article delves into what makes these manufacturers essential, the advantages of dual stage hydraulic systems, and what to look for when choosing a manufacturer.

What is a Dual Stage Hydraulic Cylinder?

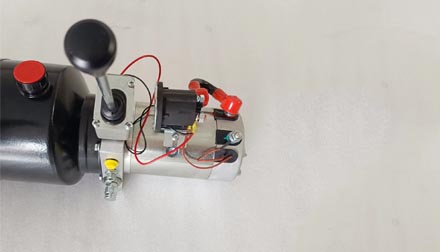

A dual stage hydraulic cylinder, often referred to as a double-acting cylinder, operates by using two distinct stages to perform powerful tasks. The unique design allows it to produce different levels of force at various stages of the hydraulic stroke. This means greater precision and control in applications ranging from heavy machinery to automotive repair. The dual stage design enables smoother operation, increased lifting capacity, and reduced energy consumption.

Advantages of Dual Stage Hydraulic Cylinders

1. Enhanced Force Output One of the primary benefits of dual stage hydraulic cylinders is their ability to offer higher force output compared to single-stage cylinders. By utilizing two stages, these cylinders can manage heavier loads and challenging tasks more effectively.

2. Improved Efficiency Dual stage cylinders can adapt their operation based on the requirements of the task at hand. For lighter loads, the cylinder can operate in a lower stage, consuming less hydraulic fluid and energy. This versatility leads to significant savings in operating costs.

3. Greater Stability and Control The two-stage operation provides better control over the movement, reducing the risk of sudden jolts or imbalances. This attribute is especially crucial in applications requiring delicate handling or precise positioning.

4. Space Saving Design In many cases, dual stage hydraulic cylinders can provide the same level of performance as larger single-stage alternatives, all within a more compact design. This space-saving characteristic is invaluable in environments where equipment size is a critical factor.

dual stage hydraulic cylinder manufacturers

Key Considerations When Choosing a Manufacturer

When seeking a dual stage hydraulic cylinder manufacturer, several factors should influence your choice.

1. Experience and Reputation It’s crucial to partner with manufacturers who have extensive experience in hydraulic technologies and a proven track record. Customer reviews, case studies, and industry reputation can offer insights into the reliability and performance of a manufacturer.

2. Customization Options Different industries may have unique requirements. A reputable manufacturer should provide the option for customization to address specific application needs, whether it’s modifying size, stroke length, or mounting configurations.

3. Quality Assurance Practices Assess the manufacturer’s quality assurance processes, including materials used, design protocols, and testing methodologies. High-quality materials and rigorous testing are essential for ensuring the longevity and reliability of hydraulic cylinders.

4. Support and Service Post-purchase support can significantly impact your operational success. Evaluate whether the manufacturer offers strong customer service, technical support, and warranty options.

5. Innovation and Technology The hydraulic cylinder industry is continually evolving. Manufacturers that invest in research and development are more likely to offer innovative solutions that improve performance and efficiency. Look for products that leverage new technologies, such as smarter hydraulic control systems.

Conclusion

Dual stage hydraulic cylinders play a pivotal role in various industrial applications, offering significant advantages in efficiency, force output, and control. As industries evolve and the demand for sophisticated hydraulic solutions increases, understanding the role of dual stage hydraulic cylinder manufacturers becomes fundamental. By considering factors such as experience, customization, quality assurance, customer support, and technological innovation, businesses can choose the right manufacturer to meet their hydraulic needs effectively. Ultimately, investing in the right dual stage hydraulic cylinder can lead to enhanced productivity, reduced energy consumption, and improved operational reliability.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025