Nov . 16, 2024 16:45 Back to list

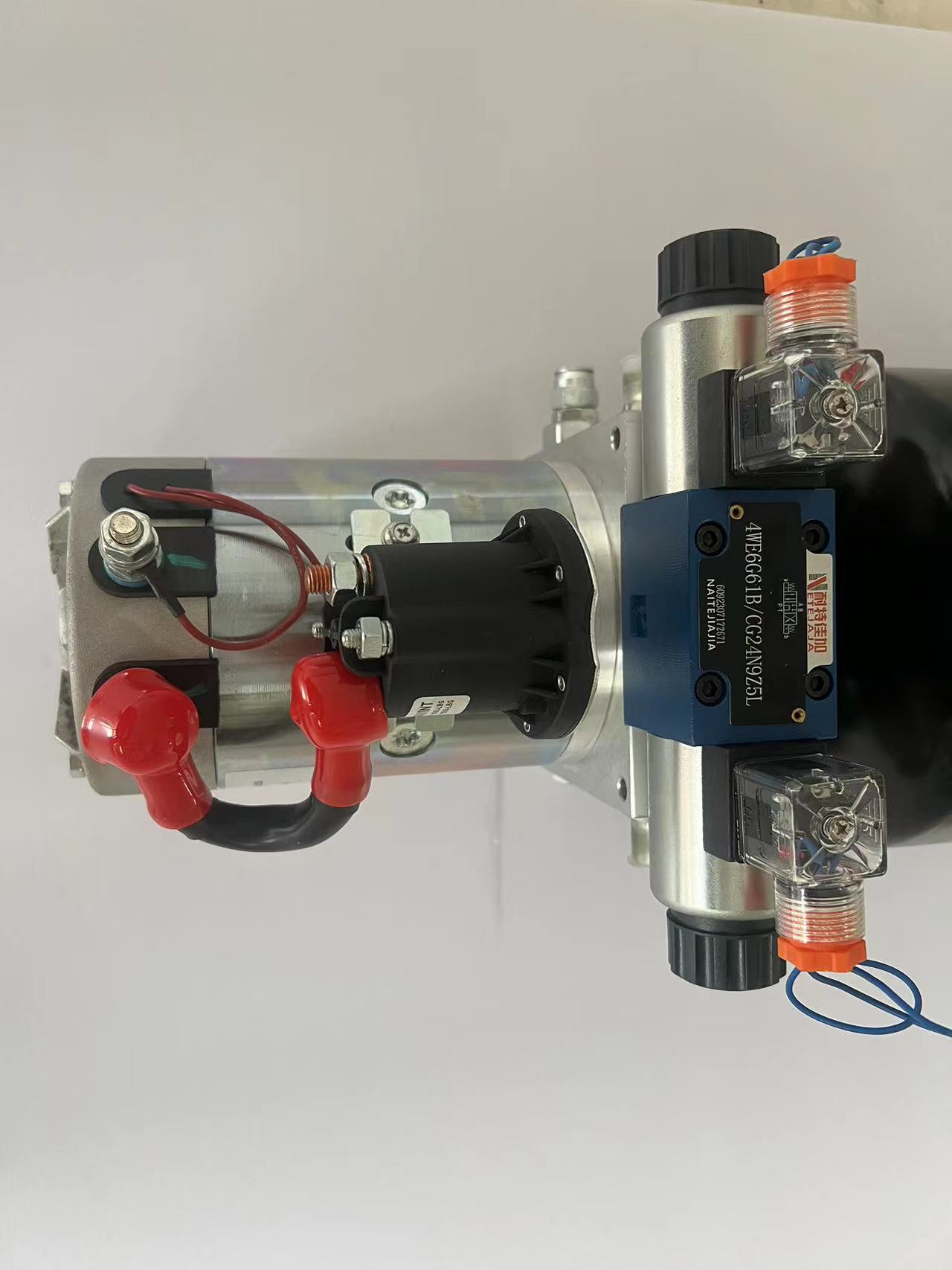

dual ram hydraulic cylinder factory

The Dual RAM Hydraulic Cylinder A Comprehensive Overview of Its Manufacturing Process and Applications

Hydraulic cylinders are vital components in various machinery and industrial applications, providing the necessary force to perform tasks ranging from lifting heavy loads to powering precise movements in automated systems. Among these, the dual RAM hydraulic cylinder has gained significant popularity for its enhanced performance and efficiency. In this article, we will delve into the manufacturing processes involved in producing dual RAM hydraulic cylinders at factories, along with their applications and advantages.

Understanding Dual RAM Hydraulic Cylinders

A dual RAM hydraulic cylinder features two rams, or pistons, that operate together to create force and movement. This design allows for greater lifting capacities and improved control compared to single RAM systems. The dual RAM system is particularly advantageous in applications requiring balanced operation or where space constraints limit the use of larger single cylinders.

Manufacturing Process

The manufacturing of dual RAM hydraulic cylinders involves several critical stages, each designed to ensure precision and durability.

1. Material Selection The first step in the manufacturing process is selecting the appropriate materials. High-strength steel is commonly used due to its excellent tensile strength and resistance to wear and tear. Additionally, seals and gaskets are made from materials like polyurethane or rubber to provide effective sealing and prevent hydraulic fluid leaks.

2. Machining the Components The main components of a dual RAM hydraulic cylinder include the cylinder body, pistons, and end caps. These parts undergo precise machining processes, such as turning, milling, and grinding, to achieve the correct dimensions and surface finishes. Advanced CNC (Computer Numerical Control) machines are often utilized to enhance accuracy and reduce production time.

3. Assembly Once the components are machined, they are assembled into a complete hydraulic cylinder. This step requires meticulous attention to detail to ensure proper alignment and fit. The rams are inserted into the cylinder body along with the seals, which are crucial for preventing hydraulic fluid from escaping.

4. Testing for Quality Assurance After assembly, each dual RAM hydraulic cylinder undergoes rigorous testing to ensure it meets industry standards and specifications. This includes pressure testing to check for leaks, endurance testing to verify operational reliability, and performance testing to assess the lifting capacity and responsiveness of the cylinder.

dual ram hydraulic cylinder factory

5. Finishing Touches The final stage of production involves surface treatments, such as painting or coating, to enhance corrosion resistance and durability. Each finished product is then inspected once more before being packaged for distribution.

Applications of Dual RAM Hydraulic Cylinders

The versatility of dual RAM hydraulic cylinders allows them to be employed in a wide array of applications across various industries

- Construction In the construction sector, these cylinders are commonly found in excavators and cranes, facilitating the lifting and moving of heavy materials. - Manufacturing Dual RAM cylinders are integral to automated machinery, providing the force necessary for processes like stamping, bending, and material handling. - Agriculture Tractors and other farming equipment utilize dual RAM hydraulic cylinders for functions such as lifting implements and adjusting attachments.

- Transportation In the transportation industry, dual RAM cylinders are used in trailers and lifting platforms, ensuring safe and efficient loading and unloading of goods.

Advantages of Dual RAM Hydraulic Cylinders

One of the primary advantages of dual RAM hydraulic cylinders is their increased stability and control. The parallel operation of two rams provides balanced lifting capabilities, reducing the risk of tipping or uneven loads. Moreover, these cylinders can achieve greater lifting capacities in compact designs, making them ideal for applications where space is limited.

Additionally, the dual RAM configuration allows for more precise control over movement, enabling tasks that require fine adjustments. This feature enhances safety and efficiency, making dual RAM hydraulic cylinders a valuable asset in various industrial applications.

Conclusion

As industries continue to evolve, the demand for reliable and efficient hydraulic systems will only grow. The dual RAM hydraulic cylinder stands out as a powerful solution, combining advanced design with excellent performance. Factories specializing in the production of these cylinders play a vital role in meeting the needs of various sectors, ensuring that machinery operates smoothly and safely. Through meticulous manufacturing processes and stringent quality control, manufacturers are paving the way for innovations in hydraulic technology.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025