Oct . 21, 2024 14:39 Back to list

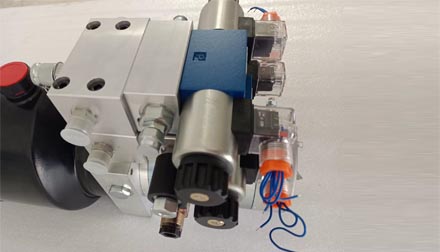

dual hydraulic cylinder factory

Understanding the Dual Hydraulic Cylinder A Vital Component in Modern Engineering

In the realm of hydraulic technology, the dual hydraulic cylinder stands out as a crucial component used in various industrial applications. Manufacturing facilities dedicated to producing these cylinders play a pivotal role in ensuring efficiency and reliability in hydraulic systems, which are utilized in construction, automotive, aerospace, and numerous other sectors.

A dual hydraulic cylinder consists of two combined hydraulic cylinders that work together to provide enhanced force and motion control. This design allows for greater lifting capacity and operational versatility compared to single-cylinder systems. The dual setup can often lead to more balanced load distribution, reducing wear and tear on equipment and prolonging its lifespan.

Factory Production and Quality Control

The process of manufacturing dual hydraulic cylinders typically begins with selecting high-quality raw materials, including steel and aluminum alloys known for their strength and durability. Advanced machining techniques, such as CNC (Computer Numerical Control) milling and turning, ensure precision in the fabrication of cylinder components.

Quality control is paramount in the production process. Reputable dual hydraulic cylinder factories implement rigorous testing protocols, including pressure tests and integrity checks, to ensure that each cylinder meets the industry standards required for safety and performance. These factories often adhere to ISO (International Organization for Standardization) certifications that guarantee the reliability and quality of their products.

dual hydraulic cylinder factory

Applications of Dual Hydraulic Cylinders

The versatility of dual hydraulic cylinders makes them applicable in many fields. In construction, for example, they are often found in excavators and backhoes, where they provide the necessary power to move heavy loads with precision. In the automotive industry, they are crucial in forming and assembly lines, where precise movements are essential for quality control.

In aerospace, dual hydraulic cylinders are used in landing gears and flight control mechanisms, where dependability is non-negotiable. Their ability to provide controllable motion and increased force is invaluable in ensuring safety and efficiency.

Future Trends in Hydraulic Cylinder Manufacturing

As the demand for more efficient and sustainable machinery grows, dual hydraulic cylinder factories are evolving. The incorporation of smart technology, such as IoT (Internet of Things) sensors, allows for real-time monitoring and diagnostics, facilitating predictive maintenance and minimizing downtime. Additionally, the ongoing development of lightweight materials aims to enhance the energy efficiency of hydraulic systems, making them more environmentally friendly.

In conclusion, the dual hydraulic cylinder is a cornerstone of modern engineering and manufacturing. The factories that produce these vital components are at the forefront of innovation, balancing quality and performance with the ever-increasing demands of various industries. As technology advances, these facilities will likely continue to develop cutting-edge solutions that further enhance the capabilities of hydraulic systems, ultimately contributing to a more efficient and sustainable future.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025