Sep . 22, 2024 23:15 Back to list

dual action hydraulic cylinder factory

Exploring the Dual Action Hydraulic Cylinder Factory A Hub of Innovation and Precision

In the realm of industrial machinery, the dual action hydraulic cylinder stands out as a critical component, enabling various applications across multiple sectors. Within this context, a dual action hydraulic cylinder factory plays a pivotal role, serving as the heart of production and innovation. In this article, we will delve into the intricacies of such a factory, the manufacturing process, and the significance of dual action hydraulic cylinders in contemporary engineering.

At its core, a dual action hydraulic cylinder is designed to convert hydraulic energy into mechanical motion, facilitating both extension and retraction functions. This bi-directional operation is essential in applications ranging from construction equipment to automotive assemblies and aerospace technologies. The unique capability of these cylinders to perform work in both directions makes them indispensable in scenarios where efficiency and power are paramount.

A dual action hydraulic cylinder factory embodies state-of-the-art technology and skilled craftsmanship. The manufacturing process typically begins with the selection of high-quality raw materials, such as steel and aluminum, which are crucial for ensuring the durability and performance of the cylinders. Advanced machinery, including CNC machines and hydraulic presses, is employed to precisely cut, shape, and assemble the components.

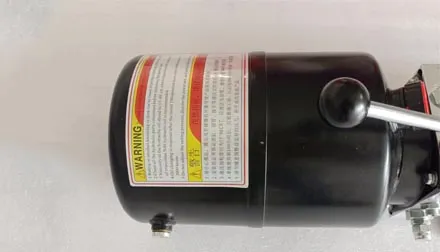

dual action hydraulic cylinder factory

Quality control is a cornerstone of the factory’s operations. Each hydraulic cylinder undergoes rigorous testing to ensure it meets industry standards and specifications. This includes pressure testing, performance evaluation, and inspection for any defects. Such meticulous attention to detail not only guarantees the reliability of the products but also instills confidence in the customers who depend on these hydraulic systems for their operations.

Moreover, innovation plays a vital role in the evolution of dual action hydraulic cylinders. Factories are continually investing in research and development to enhance the performance and efficiency of their products. This includes incorporating advanced materials, improving sealing technologies, and optimizing design for enhanced functionality. As industries evolve and demand grows for more powerful and efficient machinery, dual action hydraulic cylinder manufacturers are at the forefront of delivering cutting-edge solutions.

Sustainability is another important aspect of modern dual action hydraulic cylinder factories. With increasing awareness of environmental impacts, many manufacturers are adopting eco-friendly practices. This includes minimizing waste during production, recycling materials whenever possible, and using energy-efficient processes. Such initiatives not only contribute to environmental preservation but also improve the overall sustainability of the manufacturing sector.

In summary, the dual action hydraulic cylinder factory is a hub of innovation and precision manufacturing. By producing high-quality hydraulic cylinders that are essential for various applications, these factories play a crucial role in driving industrial advancements. Through rigorous quality control, a commitment to innovation, and sustainable practices, they ensure that their products meet the evolving needs of industries worldwide. As we continue to advance technologically, the significance of these factories and the dual action hydraulic cylinders they produce cannot be overstated, marking a vital intersection of engineering and industrial efficiency.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025