Oct . 21, 2024 22:33 Back to list

designing hydraulic cylinder production process for efficient manufacturing and quality control

Understanding the Process of Hydraulic Cylinder Production

Hydraulic cylinders are critical components in a variety of industrial and mobile applications, serving as the power source for machinery and equipment. The efficient production of hydraulic cylinders is crucial for ensuring that these components meet the high standards required for performance, durability, and safety. This article explores the different stages involved in the manufacturing of hydraulic cylinders, focusing on the significance of the drawing process in a factory setting.

The Importance of Design Drawings

Before any manufacturing begins, the first step is to create detailed design drawings. These drawings serve multiple purposes they guide fabricators in accurately assembling hydraulic cylinders, ensure compliance with engineering specifications, and provide a basis for quality control. The designs include essential dimensions, material specifications, and assembly instructions. Utilizing Computer-Aided Design (CAD) systems allows engineers to simulate the functioning of the hydraulic cylinder under different operational conditions, ensuring optimal performance.

Selecting Raw Materials

Once the design is finalized, the next stage involves selecting the appropriate raw materials. The choice of materials is crucial due to the operational conditions that hydraulic cylinders must withstand, such as high pressure and corrosive environments. Common materials include high-strength steel for the cylinder body, aluminum for lightweight applications, and various alloys that enhance characteristics like resistance to wear and fatigue. The selected materials must meet industry standards, and their quality is often verified through certification processes.

Machining Components

After sourcing the materials, the factory enters the machining phase. This involves cutting, drilling, and shaping the raw materials according to the specifications outlined in the design drawings. Machining is a critical step, as the precision with which components are created determines the overall performance of the hydraulic cylinder. High-precision machining tools, such as CNC (Computer Numerical Control) machines, are employed to achieve the tight tolerances needed for proper fit and function.

Each component of the hydraulic cylinder, including the cylinder tube, piston, and end caps, undergoes rigorous machining to ensure they align perfectly during assembly

. This accuracy is crucial, as even minor discrepancies can lead to failure in hydraulic systems.Assembly of Hydraulic Cylinders

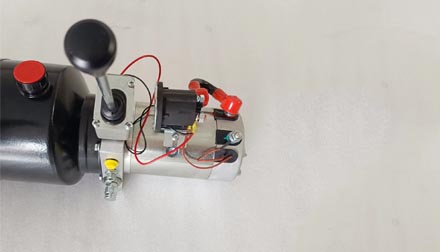

drawing hydraulic cylinder factory

Once all components are machined, the assembly process begins. This phase requires skilled technicians who follow the detailed assembly instructions derived from the original drawings. Technicians ensure that parts like seals, rods, and pistons are correctly fitted and sealed to prevent leaks. A critical aspect of this process is the application of hydraulic seals that must withstand high pressures while maintaining effectiveness.

Furthermore, this stage includes steps such as welding, if necessary, to ensure the structural integrity of the cylinder. Each assembled unit is then tested for functionality, leaks, and performance under simulated operational conditions.

Quality Control Testing

Quality control is essential in the manufacturing of hydraulic cylinders. After assembly, each cylinder undergoes a series of tests to ensure it meets the predefined standards. Testing typically includes pressure testing, where the cylinder is subjected to pressures higher than normal operating conditions to verify its strength and reliability.

Additionally, manufacturers often conduct leak tests to check for any imperfections in seals or joints. The results of these tests are documented to ensure traceability and compliance with safety regulations. Only those cylinders that pass all tests proceed to the next stage.

Final Inspection and Packaging

The final inspection is a critical step before the hydraulic cylinders are packaged and shipped. Quality assurance teams examine the finished products for any cosmetic defects, ensuring they meet aesthetic standards as well as functional ones. After thorough inspection, the cylinders are cleaned, and protective coatings may be applied to prevent corrosion during transport.

Finally, hydraulic cylinders are carefully packaged, considering their weight and fragility, to ensure they arrive at their destination without damage. Manufacturers often provide documentation, including test results and certification, to their customers, assuring them of the product's quality and reliability.

Conclusion

The production of hydraulic cylinders is a complex, multi-stage process that requires precision, quality control, and skilled labor. From the initial design drawings to the final inspection and packaging, each step is vital in ensuring that hydraulic cylinders perform efficiently and reliably in various applications. As industries continue to evolve, the importance of high-quality hydraulic cylinders remains unchanged, underscoring the need for continuous improvement in manufacturing processes.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025