Nov . 10, 2024 11:57 Back to list

High-Performance Double Action Hydraulic Cylinder for Industrial Applications

Understanding Double Stroke Hydraulic Cylinders An Overview

Hydraulic systems are integral to many industries, as they provide the power needed to perform heavy lifting and precise movements. Among the various components found in hydraulic systems, double stroke hydraulic cylinders play a critical role. This article aims to provide a comprehensive overview of these cylinders, their features, applications, and advantages.

What is a Double Stroke Hydraulic Cylinder?

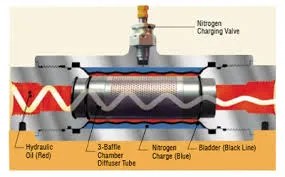

A double stroke hydraulic cylinder is a type of actuator that uses hydraulic pressure to create linear motion in two distinct strokes the extension stroke and the retraction stroke. This unique design allows the cylinder to operate efficiently, providing double the movement with a single input. The mechanism consists of a cylinder, piston, and two ports for hydraulic fluid input, enabling the piston to move in both directions.

How Does it Work?

The operation of a double stroke hydraulic cylinder is relatively straightforward. When hydraulic fluid is pumped into one side of the piston, it causes the piston to move in one direction (usually extending). Conversely, when fluid is released and directed to the other side of the piston, the piston retracts. The ability to control fluid flow precisely allows for various speed and force outputs, making these cylinders versatile for different applications.

Key Features of Double Stroke Hydraulic Cylinders

1. Durability Constructed from high-strength materials, double stroke hydraulic cylinders are designed to withstand extreme pressure and harsh working conditions, ensuring a long lifespan.

2. Efficiency They provide higher efficiency in terms of power-to-weight ratio, allowing for effective performance with minimal energy consumption.

3. Compact Size These cylinders can be designed with a compact profile, making them suitable for installations with limited space.

4. Customizable Stroke Lengths Manufacturers can produce custom stroke lengths based on specific application needs, adding to their versatility.

5. Safety Features Many models come with built-in safety mechanisms to prevent accidental overextension or retraction, ensuring safe operation in various environments.

Applications of Double Stroke Hydraulic Cylinders

Double stroke hydraulic cylinders are widely utilized in several industries, including

double stroke hydraulic cylinder product

- Construction Used in excavators, cranes, and earthmoving machinery, these cylinders facilitate lifting and moving heavy materials efficiently.

- Manufacturing In production lines, they are employed for tasks such as stamping, molding, and assembly, providing the necessary force and control.

- Agriculture Hydraulic cylinders can be found in farming equipment, enabling seamless operation of plows, harvesters, and loaders.

- Transportation They are also used in various transport vehicles, including trailers and trucks, for lifting and tilting.

- Material Handling Double stroke hydraulic cylinders have applications in conveyor systems, forklifts, and automated storage solutions.

Advantages of Using Double Stroke Hydraulic Cylinders

The use of double stroke hydraulic cylinders presents several advantages

1. Increased Productivity By allowing for back-and-forth motion with one system, these cylinders reduce the need for multiple actuators, streamlining operations.

2. Cost-Efficiency With reduced maintenance and operational costs, businesses can achieve better return on investment through the use of these devices.

3. Flexibility The ability to control movement with precision allows operators to perform various tasks efficiently, adapting to different job requirements.

4. Lower Energy Consumption By optimizing the hydraulic fluid’s route, double stroke cylinders can minimize energy use, thus contributing to more sustainable operations.

Conclusion

In conclusion, double stroke hydraulic cylinders are a vital component in modern hydraulic systems, providing effective and efficient solutions for numerous applications across different industries. Their robust design, versatility, and operational efficiency make them an ideal choice for businesses seeking to enhance productivity and performance. Whether in construction, manufacturing, or any other field, understanding the functionalities and benefits of these cylinders can lead to smarter decisions and improved operational outcomes. As technology continues to evolve, we can expect further innovations in hydraulic cylinder designs, enhancing their capabilities even more. This progress will undoubtedly expand their applications and efficiency in our increasingly mechanized world.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025