Dec . 05, 2024 05:03 Back to list

Top Manufacturers of Double-Ended Hydraulic Cylinders for Various Applications

Understanding Double-Ended Hydraulic Cylinders A Look at Leading Manufacturers

Double-ended hydraulic cylinders are pivotal components in various industrial applications, from construction machinery to material handling operations. Characterized by their dual piston rods, these cylinders allow for bidirectional force application, making them highly efficient and effective in compact spaces. As industries increasingly rely on hydraulic systems for their operational needs, the demand for top-tier manufacturers of double-ended hydraulic cylinders has surged. This article explores the significance of these cylinders, their applications, and what to look for in reliable manufacturers.

What Are Double-Ended Hydraulic Cylinders?

A double-ended hydraulic cylinder is a type of actuator that uses hydraulic fluid to create motion. Unlike single-ended cylinders, which have a rod extending from one end, double-ended cylinders possess rods on both ends. This configuration enables the cylinder to extend and retract simultaneously, thereby providing a more balanced load distribution and enhancing the force exerted during operation.

These cylinders are designed to provide high efficiency and performance, allowing for faster operation and improved control over loads. The dual piston rods mean that the same amount of hydraulic fluid can be used to exert equal force in either direction, making them ideal for tasks that require simultaneous push-pull actions.

Applications of Double-Ended Hydraulic Cylinders

Double-ended hydraulic cylinders find versatile applications across numerous industries

1. Construction In construction equipment like excavators and bulldozers, these cylinders deliver powerful lifting and digging capabilities. Their ability to work under high pressure makes them suitable for heavy-duty operations.

2. Material Handling In warehouses and manufacturing plants, double-ended cylinders are often seen in lifting devices like forklifts and conveyor systems. They facilitate smooth and efficient maneuvering of materials.

3. Agriculture Agricultural machinery, such as seeders and sprayers, utilizes these cylinders to enhance functionality and efficiency.

5. Marine Applications Many boats and ships employ double-ended hydraulic cylinders in their steering and control systems, ensuring balanced and responsive navigation.

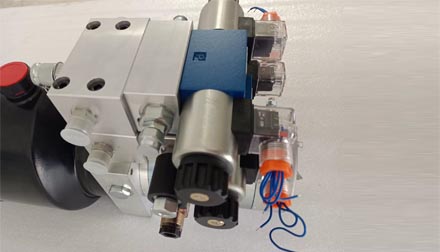

double ended hydraulic cylinder manufacturers

Choosing the Right Manufacturer

When searching for reliable manufacturers of double-ended hydraulic cylinders, various factors should be considered

1. Quality Standards Always look for manufacturers that adhere to international quality standards. Certifications such as ISO 9001 indicate a company's commitment to quality management and continuous improvement.

2. Customization Options Different applications may require unique specifications. Leading manufacturers often provide customization options that allow clients to tailor cylinders to their specific needs.

3. Technical Expertise A manufacturer with extensive experience in hydraulic technology will likely offer better design and engineering insights. Look for companies that have been in the industry for several years and have a proven track record.

4. Materials and Durability The materials used in the construction of hydraulic cylinders significantly influence their performance and lifespan. Reliable manufacturers employ high-grade materials designed to withstand high pressure and harsh working conditions.

5. Technical Support and Service Post-purchase support is crucial. A manufacturer that offers robust technical assistance, troubleshooting, and maintenance services can greatly enhance the longevity and efficiency of their products.

6. Reputation and Reviews Researching a manufacturer's reputation through customer reviews and industry feedback is invaluable. Companies with positive reviews and a solid reputation in the market are more likely to provide high-quality products.

7. Pricing and Value While cost is an important factor, it should not be the sole determinant. Assess the overall value offered by the manufacturer in terms of quality, service, and reliability.

Conclusion

Double-ended hydraulic cylinders play a crucial role in enhancing operational efficiency across various industries. The importance of selecting the right manufacturer cannot be overstated, as it directly impacts equipment performance and reliability. By understanding the key features and applications of these cylinders, along with the selection criteria for manufacturers, businesses can make informed decisions that lead to improved productivity and safety in their operations. As the industry continues to evolve, the demand for high-quality hydraulic components will only grow, making it essential for manufacturers to innovate and meet the latest technological standards.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025