Dec . 02, 2024 08:02 Back to list

double acting hydraulic cylinder company

Understanding the Double Acting Hydraulic Cylinder A Key Component in Modern Machinery

Hydraulic systems are the backbone of many industrial applications, providing the necessary force and control for various machinery. Among the essential components of these systems, the double acting hydraulic cylinder stands out as a vital tool in converting hydraulic energy into mechanical energy. This article will explore the function, advantages, and applications of double acting hydraulic cylinders, and why they are crucial to many industries today.

What is a Double Acting Hydraulic Cylinder?

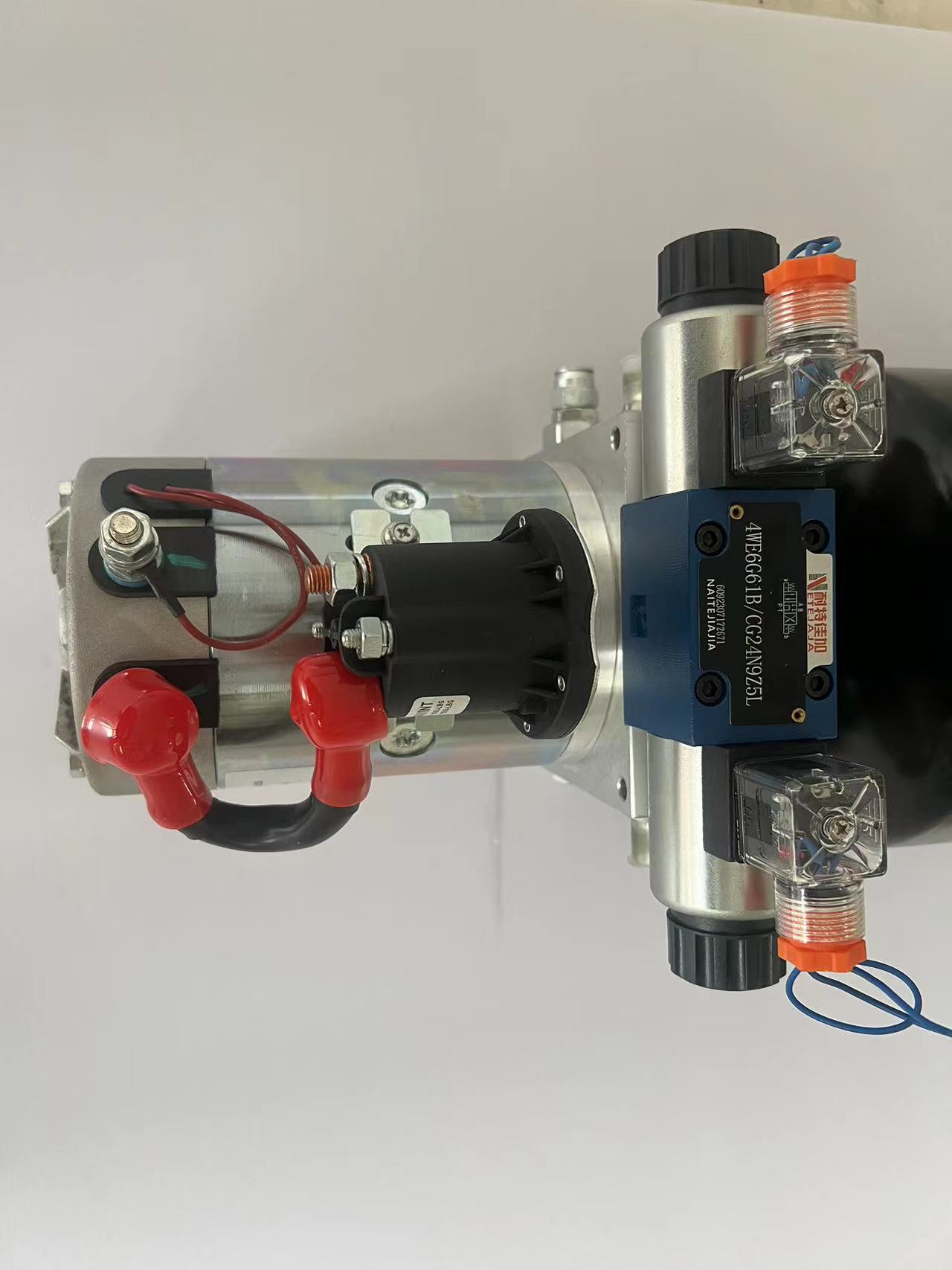

A double acting hydraulic cylinder is a type of actuator that can exert force in both directions. Unlike single acting cylinders, which can only extend or retract using hydraulic pressure on one side of the piston, double acting cylinders utilize hydraulic pressure on both sides. This design allows for greater control and efficiency in various applications, as it can both extend and retract, providing motion in both directions with minimal downtime.

How They Work

At its core, a double acting hydraulic cylinder consists of a cylinder barrel, piston, and end caps. The hydraulic fluid enters through ports at both ends of the cylinder, allowing pressure to be applied to the piston from either side. This controlled application of pressure enables complex movement and positioning. For instance, when fluid is pumped into one side of the cylinder, the piston moves in one direction. To move it back, fluid is released from that side and introduced into the opposite side, allowing precise control over the movement speed and force.

Advantages of Double Acting Hydraulic Cylinders

1. Versatility Their ability to perform work in both directions makes double acting cylinders suitable for a wide range of applications, from simple lifting tasks to complex automated systems.

2. Efficiency By using hydraulic pressure on both sides of the piston, these cylinders can achieve faster cycle times and greater force output compared to single acting cylinders, making them ideal for heavy-duty tasks.

3. Control The functionality of double acting cylinders allows for precise control of speed and positioning, which is essential in applications where accuracy is critical.

4. Durability Modern double acting hydraulic cylinders are designed for longevity, with many featuring seals and materials that can withstand harsh environments, increasing their reliability and reducing maintenance costs.

Applications Across Industries

Double acting hydraulic cylinders have become indispensable in various industries, including

double acting hydraulic cylinder company

- Construction Used in excavators, backhoes, and cranes, these cylinders provide the power needed for lifting heavy loads and performing various tasks on construction sites.

- Manufacturing In manufacturing processes, double acting cylinders are employed in automated machinery for assembly, packaging, and material handling, enhancing productivity and precision.

- Automotive Hydraulic cylinders are crucial in automotive systems, such as in the lifting mechanisms of car lifts and in suspension systems, ensuring smooth and efficient operations.

- Agriculture Agricultural machinery, including tractors and harvesters, relies on double acting hydraulic cylinders for tasks like lifting, pushing, and pulling, which are essential for effective fieldwork.

- Marine In the marine industry, these cylinders are used in steering systems, deck machinery, and cargo handling, demonstrating their versatility in challenging environments.

Choosing the Right Double Acting Hydraulic Cylinder

When selecting a double acting hydraulic cylinder for a specific application, several factors should be considered

- Stroke Length Determine the required extension and retraction length for the intended application.

- Pressure Rating Ensure the cylinder can handle the specific pressure requirements of your system.

- Mounting Options Assess the mounting style that fits best with your machinery to ensure proper installation and function.

- Environment Consider the operating environment, including temperature, contaminants, and exposure to chemicals, which can affect the cylinder's performance and longevity.

Conclusion

Double acting hydraulic cylinders play a crucial role in the efficiency and effectiveness of modern machinery across a multitude of sectors. Their unique design, allowing for movement in both directions, coupled with their robustness and reliability, makes them a preferred choice for engineers and manufacturers alike. As industries continue to evolve and demand for more sophisticated hydraulic systems increases, the role of double acting hydraulic cylinders will undoubtedly remain significant, driving innovation and productivity in countless applications. Whether in construction, manufacturing, or agriculture, understanding and utilizing this essential component is key to achieving operational excellence.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025