Oct . 11, 2024 03:00 Back to list

double acting hollow hydraulic cylinder companies

The Rise of Double Acting Hollow Hydraulic Cylinder Companies

In the evolving landscape of industrial manufacturing and construction, the demand for efficient, reliable, and versatile machinery has never been more significant. Among the various types of hydraulic equipment, double acting hollow hydraulic cylinders have emerged as a preferred choice for many industries due to their unique features and functionalities. This article delves into the characteristics of double acting hollow hydraulic cylinders, their applications, and the emergence of companies specializing in their design and manufacturing.

Understanding Double Acting Hollow Hydraulic Cylinders

A double acting hollow hydraulic cylinder is a type of actuator that uses hydraulic power to generate linear motion. Unlike traditional single-acting cylinders that use hydraulic fluid to move in one direction, double acting cylinders utilize fluid pressure to work both ways—extending and retracting. This two-way operation allows for greater flexibility and efficiency in applications ranging from material handling to construction equipment.

One of the defining features of hollow hydraulic cylinders is their hollow bore, which enables the passage of other components such as rods or cables through the cylinder itself. This design is particularly beneficial in applications requiring a compact and lightweight solution, such as in robotics and machinery where space and weight constraints are critical.

Applications in Various Industries

Double acting hollow hydraulic cylinders find applications across multiple sectors, including construction, automotive, manufacturing, and aerospace. Here are some notable uses

1. Construction These cylinders are widely used in heavy machinery, such as excavators and loaders, where they help lift and move heavy materials efficiently. Their robust design can withstand high pressure and harsh conditions, making them ideal for construction sites.

2. Manufacturing In manufacturing facilities, double acting cylinders are integral to automated systems. They assist in assembly lines, packaging machinery, and robotics, where precise movement and control are essential for productivity and safety.

3. Automotive The automotive industry utilizes these cylinders for various applications, including lifting vehicles during maintenance and testing hydraulic systems in vehicles. Their ability to exert force in both directions enhances their usability in testing scenarios.

double acting hollow hydraulic cylinder companies

4. Aerospace In aerospace, these cylinders are employed in landing gear systems and other critical components that require reliable and consistent performance under varying pressures.

The Emergence of Specialized Companies

The growing need for advanced hydraulic solutions has led to the emergence of numerous companies specializing in the design and manufacturing of double acting hollow hydraulic cylinders. These companies range from large manufacturers with extensive product lines to smaller, niche players focusing on customized solutions.

1. Innovation and Customization Many of these companies invest in research and development to improve cylinder performance and durability. They offer customization options tailored to specific client needs, addressing unique challenges faced in various applications.

2. Sustainability As industries strive for sustainability, companies are exploring eco-friendly materials and processes for cylinder production. This shift not only reduces environmental impact but also aligns with the changing preferences of consumers and industries towards green technology.

3. Global Reach and Local Expertise With globalization, many companies have expanded their reach to international markets while maintaining local expertise. This allows them to provide localized support and service, ensuring that clients receive the best possible solutions tailored to their specific environments.

4. Quality Assurance Leading manufacturers adhere to strict quality control standards, often obtaining certifications such as ISO to validate their commitment to excellence. This focus on quality not only ensures reliability but also builds trust with customers who depend on these critical components for safety and efficiency.

Conclusion

The double acting hollow hydraulic cylinder is a vital component in modern industrial applications, offering versatility and efficiency that meet the demands of various sectors. With the rise of companies dedicated to their design and manufacturing, the future looks promising for this technology. As industries continue to evolve, the need for innovative and reliable hydraulic solutions will drive further advancements, making double acting hollow hydraulic cylinders integral to achieving success in an increasingly competitive market. As these companies push the boundaries of what is possible, they contribute significantly to the growth and efficiency of industries worldwide.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

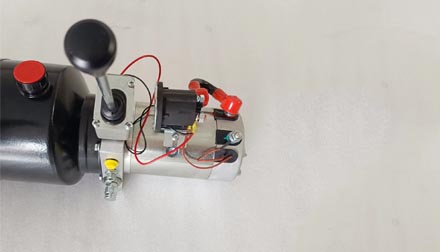

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025