Aug . 29, 2024 17:21 Back to list

double acting cylinder hydraulic factory

Understanding Double Acting Cylinder Hydraulic Systems in Manufacturing

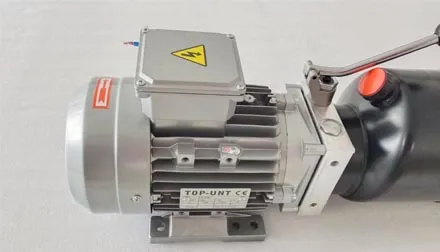

Double acting cylinders are pivotal in modern hydraulic systems, especially in manufacturing setups where efficiency and precision are paramount. These cylinders are designed to use hydraulic fluid in both the forward and return strokes, allowing for more controlled and powerful linear motion. This dual-action mechanism significantly enhances productivity and is widely adopted in various industrial applications.

One of the key advantages of double acting cylinders is their ability to produce force in both directions. Unlike single acting cylinders, which can only exert force in one direction and rely on a spring for the return stroke, double acting cylinders utilize hydraulic pressure to push and retract. This capability enables them to perform complex tasks, such as lifting, pushing, and pulling heavy loads with minimal effort. The controlled movement offered by double acting cylinders makes them ideal for tasks that require consistent precision.

In a typical hydraulic system, the double acting cylinder is connected to a pump that supplies hydraulic fluid. When hydraulic fluid is sent to one side of the cylinder, it creates a pressure differential that pushes the piston in one direction. Simultaneously, fluid is expelled from the other side of the cylinder, allowing for a smooth return. This back-and-forth motion is what drives various machinery in factories, including presses, lifts, and robotics.

double acting cylinder hydraulic factory

Manufacturers often opt for double acting cylinders due to their robustness and reliability. These cylinders are engineered to endure high pressure and heavy workloads, making them suitable for rigorous industrial environments. Their design also allows for easy maintenance, which is crucial in minimizing downtime in production lines. By choosing reliable hydraulic components, factories can ensure their operations remain efficient and that they can meet production demands consistently.

Moreover, the versatility of double acting cylinders means they can be customized for specific applications. Manufacturers can adjust factors such as bore size, stroke length, and pressure ratings, tailoring the cylinders to meet unique operational requirements. This flexibility enables businesses to enhance their capabilities and innovate their processes, positioning themselves competitively in the market.

In conclusion, double acting cylinders play a crucial role in the hydraulic systems of modern manufacturing. Their ability to deliver powerful and precise movements in both directions makes them indispensable for a wide range of applications. As technology continues to evolve, the efficiency, reliability, and versatility of double acting cylinders will undoubtedly contribute to the advancement of manufacturing processes. For industries aiming for excellence and productivity, investing in high-quality double acting cylinders is not just an option; it is a necessity.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025