Dec . 10, 2024 06:23 Back to list

displacement hydraulic cylinder factories

Displacement Hydraulic Cylinder Factories Pioneering Precision in Engineering

In today’s fast-paced industrial landscape, the demand for precision and efficiency is paramount. Among the pivotal components driving machinery and equipment are hydraulic cylinders. Displacement hydraulic cylinders, in particular, play a critical role in various applications, ranging from construction and manufacturing to automotive and aerospace industries. This article explores the significance of displacement hydraulic cylinder factories, highlighting their importance in engineering and production.

Understanding Displacement Hydraulic Cylinders

At its core, a displacement hydraulic cylinder is a mechanical device that converts hydraulic energy into linear motion. It achieves this by utilizing hydraulic fluid to create pressure, which subsequently moves the piston within the cylinder. The displacement refers to the volume of fluid displaced by the piston, which directly correlates to the force and speed exerted by the cylinder. These cylinders are renowned for their robustness and efficiency, making them indispensable in heavy-duty applications.

The Role of Factories in Production

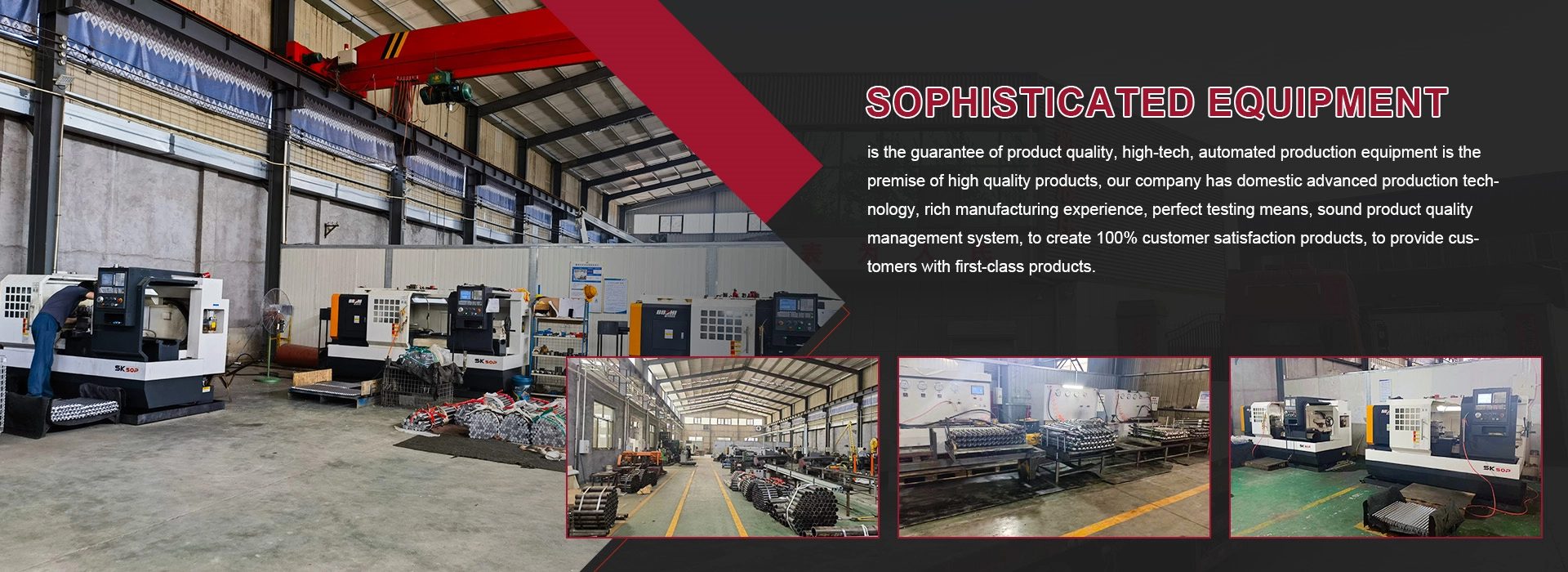

Displacement hydraulic cylinder factories are specialized facilities dedicated to the design, manufacturing, and assembly of these hydraulic systems. The intricate process begins with research and development, where engineers focus on improving functionality, durability, and performance. This R&D phase is crucial, as it ensures that the cylinders meet rigorous industry standards and are tailored to the specific needs of customers.

Once the design is finalized, the production phase kicks in. Factories utilize advanced machinery and automation to manufacture cylinder components with unparalleled precision. The processes involved include machining, welding, and surface treatment—each critical in ensuring that the final product can withstand the harsh conditions of industrial use. Quality control measures are firmly embedded throughout the production cycle, ensuring that each hydraulic cylinder meets stringent safety and performance criteria.

displacement hydraulic cylinder factories

Technological Advancements

The landscape of hydraulic cylinder manufacturing is constantly evolving, driven by technological advancements. Modern displacement hydraulic cylinder factories are increasingly incorporating smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) into their operations. These technologies facilitate real-time monitoring of production processes, enhancing efficiency and reducing waste.

Additionally, advancements in materials science are playing a significant role in the evolution of hydraulic cylinders. Factories are now able to source high-performance materials that offer greater strength-to-weight ratios and improved resistance to wear and corrosion. This results in more reliable and longer-lasting cylinders, ultimately leading to reduced maintenance costs for end-users.

Environmental Considerations

In an era of heightened environmental awareness, displacement hydraulic cylinder factories are also adapting their practices to minimize their ecological footprint. This involves optimizing manufacturing processes to reduce energy consumption and waste. Some factories are implementing recycling programs for hydraulic fluids and materials, emphasizing sustainability in their operations. By focusing on eco-friendly practices, manufacturers are contributing to a greener future while maintaining competitiveness in the marketplace.

Conclusion

Displacement hydraulic cylinder factories are at the forefront of modern engineering, providing essential components that power a myriad of industries. Their commitment to precision, technological innovation, and sustainable practices positions them as key players in the global economy. As industries continue to evolve, these factories will undoubtedly adapt, ensuring that they meet the ever-increasing demands for quality and performance in hydraulic systems. The future of hydraulic cylinders is bright, and the factories that manufacture them will play a pivotal role in shaping that future. With a blend of expertise, technology, and sustainability, they are not just producing cylinders; they are driving the heart of industry forward.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025