Nov . 07, 2024 12:39 Back to list

Hydraulic Cylinder Manufacturers for Desk and Office Chairs Production

The Essential Role of Desk Chair Hydraulic Cylinders in Modern Workspaces

In the ever-evolving landscape of modern work environments, ergonomics plays a pivotal role in enhancing productivity and comfort. Among the various components that contribute to this ergonomics revolution, the hydraulic cylinder in desk chairs stands out for its significance and functionality. As offices now adopt more dynamic and flexible layouts, understanding the manufacturing and engineering of hydraulic cylinders that are found in many desk chairs becomes increasingly important.

What is a Hydraulic Cylinder?

At its core, a hydraulic cylinder in a desk chair is a crucial mechanism that allows for the adjustment of chair height, enabling personalization of seating for users of varying sizes. The cylinder operates through hydraulic fluid, which creates a controlled mechanism for lifting or lowering the chair. This functionality is not only about comfort but also about promoting a healthier workspace. Properly adjusting the chair height can prevent a plethora of musculoskeletal issues that arise from prolonged poor posture, thereby improving overall employee well-being.

The Manufacturing Process

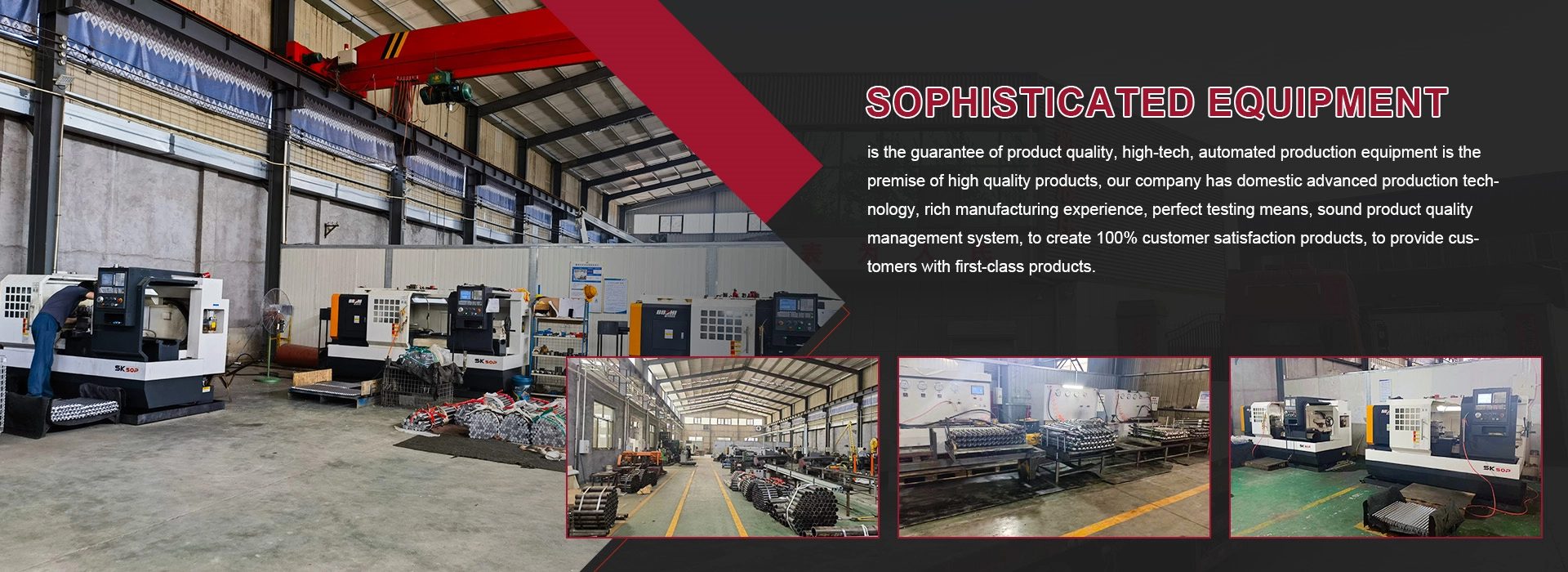

The production of high-quality hydraulic cylinders for desk chairs is a specialized process that involves multiple steps, necessitating precision engineering and a deep understanding of material science. Factories that produce these components generally adhere to stringent quality control standards to ensure durability and safety.

1. Material Selection The foundation of a reliable hydraulic cylinder is the choice of materials. Typically, manufacturers utilize high-strength steel or aluminum to ensure the cylinder can withstand the stresses of frequent use. The material also needs to be resistant to corrosion, as it is often exposed to various substances that could degrade its performance over time.

2. Machining and Fabrication Once the materials are selected, the next step involves machining. This process shapes the metal into the required form with high precision. Sophisticated machinery and technology, including CNC (Computer Numerical Control) machines, provide the accuracy needed for the intricate parts of the hydraulic cylinders.

3. Assembly After fabrication, the different components of the hydraulic cylinder, including seals, pistons, and the cylinder itself, are assembled. This stage demands skilled labor, as even small discrepancies can lead to malfunctions. Factories employ trained technicians to ensure each part is assembled correctly.

desk chair hydraulic cylinder factories

4. Testing Before the hydraulic cylinders are dispatched for use in desk chairs, they undergo rigorous testing. This includes pressure testing and quality assurance checks to ensure each cylinder meets industry standards and can function reliably under normal office conditions.

The Importance of Quality

The hydraulic cylinder's quality directly impacts its performance and longevity. A well-manufactured hydraulic cylinder provides smooth height adjustments and can support a significant amount of weight, contributing to the overall functionality of desk chairs. In contrast, subpar products can lead to dysfunction, such as sticking or failing to hold height, which can drastically reduce user satisfaction and lead to increased costs due to replacements.

Future Trends in Hydraulic Cylinder Manufacturing

As technology advances, so do the manufacturing processes of hydraulic cylinders. Factories are increasingly integrating automation and smart technology into their production lines, enhancing efficiency and precision. Innovations in materials, such as lighter composites and more durable coatings, are also being explored to improve the performance and ergonomics of desk chairs.

Moreover, sustainability is becoming an important focus. Many manufacturers are now looking at eco-friendly production methods and materials to minimize their environmental footprint. This shift not only caters to the growing demand for sustainable products but also aligns with corporate social responsibility goals that many companies strive to achieve.

Conclusion

In summary, desk chair hydraulic cylinders may seem like a minor component in the vast landscape of office furniture, but their role is indeed vital. The factories that specialize in their production ensure that each cylinder is crafted with care, precision, and quality in mind. As workplaces continue to evolve, the importance of ergonomic solutions, like height-adjustable chairs, will only grow. Understanding the manufacturing process of hydraulic cylinders allows consumers and business leaders alike to appreciate the engineering marvels that help create a productive and health-conscious work environment.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025