Nov . 18, 2024 05:13 Back to list

Hydraulic Cylinder Suppliers and Manufacturers for Efficient Fluid Power Solutions

The Role of Cylinder Manufacturers in Hydraulic Systems

Hydraulic systems have become essential in various industrial applications, from construction machinery to automotive manufacturing. A critical component of these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical energy. The importance of hydraulic cylinders in ensuring the efficiency and effectiveness of machinery cannot be overstated. This article delves into the role of hydraulic cylinder manufacturers, their processes, and the significant contributions they make to the industry.

Understanding Hydraulic Cylinders

Hydraulic cylinders are devices that use pressurized fluid to produce linear motion and force. They consist of a cylinder barrel, a piston, and two end caps. The hydraulic fluid enters the cylinder, forcing the piston to move, which creates the desired force and motion to lift, push, or pull loads. Due to their versatility, cylinders are widely used in forklifts, excavators, agricultural machinery, and more.

The Manufacturing Process

Hydraulic cylinder manufacturers follow a meticulous production process to ensure the reliability and performance of their products. The manufacturing process typically includes several key steps

1. Design and Engineering Before manufacturing begins, engineers design the hydraulic cylinder according to specific requirements, considering factors such as load capacity, bore size, and stroke length. Advanced simulation software is often employed to optimize the design for performance and durability.

2. Material Selection The choice of materials is crucial in the construction of hydraulic cylinders. Manufacturers predominantly use high-strength steel or aluminum, which can withstand the pressures and stresses in hydraulic systems. Corrosion-resistant coatings may also be applied to enhance longevity.

3. Machining After material selection, the manufacturing involves precision machining. Components are cut, shaped, and finished using CNC (Computer Numerical Control) machines to achieve exact specifications. This stage is critical, as even minor discrepancies can lead to cylinder failure.

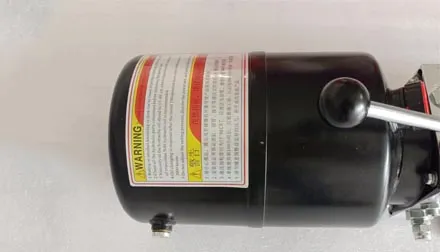

cylinder in hydraulic system manufacturers

4. Assembly Following machining, the components are assembled. This process includes the installation of seals, rods, and end caps. Special care is taken to ensure that seals are properly placed to prevent hydraulic fluid leakage, which can compromise system performance.

5. Testing Once assembled, hydraulic cylinders undergo rigorous testing. Manufacturers simulate operational conditions to ensure that each cylinder meets safety and performance standards. Pressure tests, leak tests, and endurance tests are common practices.

Innovation and Customization

Today’s hydraulic cylinder manufacturers are focusing on innovation and customization to meet the ever-evolving demands of industries. With the rise of automation and smarter machinery, manufacturers are developing cylinders that are more compact, lighter, and more efficient. Custom-built cylinders tailored to specific applications are becoming increasingly popular. These bespoke solutions allow companies to optimize their hydraulic systems for unique requirements, enhancing productivity.

Industry Impact

The quality and reliability of hydraulic cylinders directly impact the performance of hydraulic systems and, consequently, the overall productivity of industrial operations. Reputable manufacturers implement stringent quality control measures to ensure their products are durable and efficient. In addition, as industries aim to become more sustainable, cylinder manufacturers are exploring eco-friendly materials and processes, contributing to environmentally conscious manufacturing practices.

Conclusion

In summary, hydraulic cylinder manufacturers play a crucial role in the functionality and efficiency of hydraulic systems across various industries. Through precision engineering, high-quality materials, and innovative practices, these manufacturers ensure that hydraulic cylinders are reliable tools that drive industrial performance. As technology advances, we can expect further enhancements in hydraulic cylinder design and production, paving the way for even more effective applications in the future.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025