Nov . 29, 2024 19:47 Back to list

Hydraulic Cylinder Pump Solutions for Efficient Fluid Power Systems and Applications

Understanding Cylinder Hydraulic Pumps A Comprehensive Overview

Hydraulic pumps play a fundamental role in various industrial applications, providing the necessary force needed to operate machinery and equipment. Among the many types of hydraulic pumps, the cylinder hydraulic pump stands out due to its efficiency and versatility. This article will delve into the essential features, applications, and benefits of cylinder hydraulic pumps, aiding readers in understanding why these pumps are integral to modern hydraulic systems.

What Is a Cylinder Hydraulic Pump?

A cylinder hydraulic pump functions by converting mechanical energy into hydraulic energy via the movement of a piston within a cylinder. When the piston moves, it either draws hydraulic fluid into the cylinder or pushes it out, generating pressure that can be harnessed to perform work. These pumps can be powered by electric motors, internal combustion engines, or other sources of mechanical energy.

Key Components

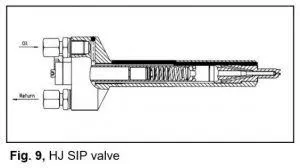

The main components of a cylinder hydraulic pump include the cylinder, piston, inlet and outlet valves, and hydraulic fluid. The cylinder serves as the chamber where hydraulic fluid is manipulated. The piston, which moves within the cylinder, is responsible for creating the pressure change necessary to control fluid flow. Inlet and outlet valves manage the entry and exit of hydraulic fluid, ensuring that the system operates efficiently.

Applications in Various Industries

cylinder hydraulic pump product

Cylinder hydraulic pumps are widely used across a variety of sectors. In construction, for instance, they power heavy equipment such as excavators, bulldozers, and hydraulic lifts. In manufacturing, these pumps play a crucial role in machinery that requires high force output, such as stamping presses and injection molding machines. They are also prevalent in automotive applications, including braking systems and automotive lifts.

Moreover, cylinder hydraulic pumps find applications in the agricultural sector, where they are used in equipment like tractors and harvesters. In the energy sector, they can help manage hydraulic systems in wind turbines and other renewable energy solutions. Their ability to provide high pressure with relatively compact designs makes them ideal for diverse use cases.

Advantages of Cylinder Hydraulic Pumps

One of the primary advantages of cylinder hydraulic pumps is their efficiency in transforming energy. Because they can generate high amounts of torque and force, they are capable of handling significant loads without requiring a large physical footprint. Additionally, the ability to control the speed and direction of hydraulic fluid flow allows for fine-tuning and precision in operations, making them suitable for tasks that demand accuracy.

Furthermore, cylinder hydraulic pumps are known for their reliability and durability. Constructed from high-quality materials, they can withstand harsh operating conditions and provide consistent performance over time. Regular maintenance also helps prolong their lifespan, contributing to overall operational efficiency.

Conclusion

In conclusion, cylinder hydraulic pumps are essential components in a wide range of applications, from industrial machinery to agricultural equipment. Their ability to convert mechanical energy into effective hydraulic power, combined with their efficiency and reliability, makes them a popular choice for engineers and operators alike. As industries continue to evolve and technology advances, the role of cylinder hydraulic pumps will remain critical, contributing to the advancements in hydraulic systems worldwide. Understanding their functionality and applications is imperative for anyone involved in systems that rely on hydraulic energy.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025