Nov . 23, 2024 06:02 Back to list

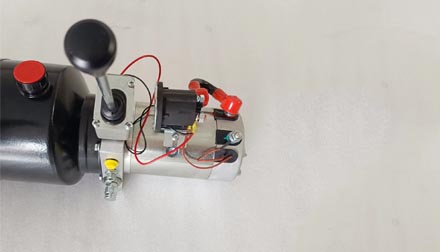

custom wear ring hydraulic cylinder

Custom Wear Rings for Hydraulic Cylinders Enhancing Performance and Durability

Hydraulic cylinders are vital components in various industries, from construction and manufacturing to automotive and aerospace. They are designed to convert hydraulic energy into mechanical force, enabling heavy machinery to operate efficiently. However, the performance and longevity of hydraulic cylinders heavily depend on the components used within, particularly wear rings. Custom wear rings play a crucial role in enhancing the efficiency and durability of hydraulic cylinders, offering numerous advantages that can significantly impact their overall functionality.

The Importance of Wear Rings

Wear rings are designed to support the piston within a hydraulic cylinder, providing a stable surface for the piston to slide against while minimizing metal-to-metal contact. This is crucial because excessive friction can lead to premature wear and tear, resulting in costly downtimes and repairs. Wear rings not only reduce friction but also help maintain proper alignment of the piston, ensuring smooth operation and improved sealing against hydraulic fluid leaks. When wear rings are tailored to specific applications, they can greatly enhance the performance of hydraulic systems.

Benefits of Custom Wear Rings

1. Tailored Solutions One of the primary advantages of custom wear rings is the ability to design rings that meet specific dimensions, materials, and performance standards. Each hydraulic cylinder may operate under different conditions, including varying pressure levels, temperatures, and exposure to harsh environments. Customization allows manufacturers to create wear rings that are perfectly suited for these unique conditions, ensuring optimal performance.

custom wear ring hydraulic cylinder

2. Material Optimization The choice of material for wear rings is critical. Custom wear rings can be manufactured from a variety of materials, including polyurethane, nylon, or specialized thermoplastics, each offering distinct benefits. For instance, polyurethane rings provide excellent wear resistance and are effective in high-pressure applications, while nylon rings are known for their low friction properties. By selecting the appropriate material, manufacturers can extend the life of wear rings and improve the overall efficiency of hydraulic cylinders.

3. Improved Performance Custom wear rings are engineered to enhance the performance of hydraulic cylinders. By minimizing friction and providing excellent wear resistance, these rings allow for smoother operation, better energy efficiency, and reduced maintenance costs. This translates to increased productivity and lower operational downtime, ultimately benefiting the bottom line of businesses reliant on hydraulic systems.

4. Cost-Effective Solutions Investing in custom wear rings can lead to significant cost savings in the long run. Although the initial investment may be higher than using standard off-the-shelf options, the reduced need for maintenance, extended lifespan of hydraulic components, and increased efficiency can offset these costs. Custom wear rings are designed to last longer and perform better, making them a wise investment for any organization utilizing hydraulic cylinders.

Conclusion

In conclusion, custom wear rings are essential components that significantly enhance the performance and longevity of hydraulic cylinders. By providing tailored solutions, optimizing materials, and improving overall efficiency, these custom components help organizations maximize their productivity while minimizing downtime and repair costs. As industries continue to rely on hydraulic systems for various applications, the role of custom wear rings becomes increasingly vital in ensuring their smooth and reliable operation. Investing in quality, customized wear rings can be a game changer for businesses, leading to enhanced performance and cost savings over time.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025