Nov . 16, 2024 08:35 Back to list

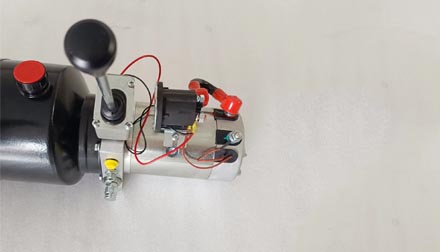

custom stepper hydraulic cylinder

Custom Stepper Hydraulic Cylinder An Essential Component for Modern Machinery

In recent years, the advancement of technology has paved the way for more sophisticated machinery across various industries. Among these innovations, the custom stepper hydraulic cylinder has gained significant attention for its reliability, efficiency, and versatility. This article explores the key attributes, applications, and benefits of custom stepper hydraulic cylinders, particularly in the context of modern manufacturing and automation processes.

Understanding Stepper Hydraulic Cylinders

A stepper hydraulic cylinder combines the functionalities of traditional hydraulic actuators with the precision control of stepper motors. This hybrid design allows for precise control over linear motion, making it ideal for applications that require exact positioning and repeatability. Unlike traditional hydraulic cylinders that rely solely on hydraulic fluid pressure for movement, the integration of stepper technology allows for finer adjustments. This can be particularly advantageous in scenarios where high levels of accuracy are paramount.

The custom aspect of these hydraulic cylinders refers to the ability to tailor the design and operation parameters to fit specific application requirements. Manufacturers can modify dimensions, pressure ratings, stroke lengths, and materials to ensure optimal performance in unique environments.

Key Applications

1. Manufacturing Automation In factories, custom stepper hydraulic cylinders are often used in robotic arms and conveyor systems where tasks such as lifting, pushing, or assembling components require precision. Their ability to make incremental adjustments means they can efficiently handle complex automation tasks that would otherwise be impossible with traditional hydraulic systems.

2. Aerospace and Aviation The aerospace industry demands the highest levels of safety and accuracy. Custom stepper hydraulic cylinders are employed in mechanisms for landing gear, control surfaces, and cargo doors, where precise movements are critical. Their reliability under varying pressure conditions makes them ideal for such high-stakes environments.

3. Medical Equipment Custom hydraulic cylinders play a pivotal role in medical devices, including surgical robots and diagnostic equipment. The precision of stepped movements allows for delicate operations, reducing the risk of human error and improving patient outcomes.

4. Automotive In automotive manufacturing, these cylinders are often used for applications such as molding, assembly, and testing. The ability to design custom hydraulic systems enables automotive manufacturers to optimize workflows and enhance product quality.

custom stepper hydraulic cylinder

5. Construction In construction machinery, custom stepper hydraulic cylinders can be used in cranes, excavators, and other heavy equipment. Their controlled movements allow for safe lifting and positioning of materials, contributing to increased efficiency on job sites.

Benefits of Custom Stepper Hydraulic Cylinders

- Precision and Accuracy One of the most significant advantages of a stepper hydraulic cylinder is its precision. The integration of a stepper motor allows for micro-stepping, enabling exact positional control that is crucial in high-precision applications.

- Reduced Cycle Times With faster response times than traditional hydraulic systems, custom stepper hydraulic cylinders can significantly reduce cycle times in manufacturing processes, leading to increased productivity and efficiency.

- Lower Energy Consumption Custom designs can be optimized for energy efficiency, reducing power requirements while maintaining performance. This is particularly important in industries focusing on sustainability and cost reduction.

- Customization Flexibility The ability to customize these hydraulic cylinders for specific applications means that businesses can achieve better results tailored to their unique operational needs. This customization can lead to enhanced performance, safety, and equipment longevity.

- Durability and Reliability Custom stepper hydraulic cylinders are built to withstand harsh conditions common in industrial settings. Their robust construction ensures long-term reliability, reducing maintenance costs and downtime.

Conclusion

As industries continue to evolve and demand more sophisticated solutions, custom stepper hydraulic cylinders stand out as a critical component in modern machinery. Their blend of precision, efficiency, and reliability makes them indispensable in various applications, from manufacturing automation to aerospace. By investing in customized solutions, businesses can enhance their operational capabilities and maintain a competitive edge in today's fast-paced market. The future of automation and machinery innovation will undoubtedly rely on the advancements made possible by these versatile hydraulic systems.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025