Oct . 30, 2024 17:08 Back to list

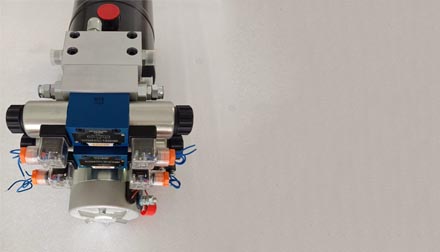

custom priming hydraulic cylinder

Custom Priming Hydraulic Cylinders Enhancing Efficiency and Versatility

Hydraulic cylinders are integral components in various industrial applications, providing the necessary force to move or lift heavy loads. Among the innovations in this field, custom priming hydraulic cylinders have emerged as a significant advancement, allowing for greater flexibility, efficiency, and effectiveness in hydraulic systems.

What Are Custom Priming Hydraulic Cylinders?

Custom priming hydraulic cylinders are specially designed hydraulic cylinders that are tailored to meet specific operational requirements. Unlike standard cylinders, which may not address unique demands, custom solutions provide the opportunity to modify key features such as size, capacity, stroke length, and mounting configurations. The term priming often refers to the initial filling of the hydraulic fluid, ensuring that the system is ready for efficient operation without air entrapment.

Importance of Customization

The need for customization arises from the diverse range of industries utilizing hydraulic systems, including construction, agriculture, manufacturing, and automotive. Each industry may have different needs regarding load capacities, operating environments, and installation constraints. For example, a hydraulic cylinder used in a compact excavator must fit in a limited space while providing significant lifting power, while cylinders used in heavy-duty trucks may prioritize capacity over compactness. Custom priming hydraulic cylinders can be designed to fit these specific use cases, ensuring optimal performance.

Benefits of Custom Priming Hydraulic Cylinders

custom priming hydraulic cylinder

1. Increased Efficiency Custom-designed hydraulic cylinders can improve system efficiency by minimizing energy loss and ensuring that the hydraulic system operates at its peak performance. Tailoring the design to fit the application can lead to better responsiveness, reduced cycle times, and overall operational efficiency.

2. Improved Reliability By addressing the unique stresses and operational conditions in which these hydraulic cylinders will function, custom designs lead to enhanced durability and reliability. This reduces maintenance costs and downtime, as equipment is less likely to fail under high stress.

3. Optimal Performance Each application has specific requirements regarding speed, load, and environmental conditions. Custom priming hydraulic cylinders can be engineered with features like integrated cushioning to control speed and prevent damage to the cylinder or the machinery it's part of, thereby optimizing performance.

4. Adaptability to Environment Many industries operate in harsh environments, requiring hydraulic systems to withstand extreme temperatures, corrosive substances, or other challenging conditions. Custom hydraulic cylinders can be designed with robust materials and protective coatings to ensure longevity and reliability.

5. Cost-Effective Solutions Though custom priming hydraulic cylinders may involve higher initial investment, the long-term savings from reduced maintenance, downtime, and increased efficiency can outweigh these costs. Additionally, businesses can avoid the need for frequent replacements or modifications, further justifying the investment.

Conclusion

Custom priming hydraulic cylinders represent a significant evolution in hydraulic technology, providing tailored solutions that enhance functionality, efficiency, and reliability. Industries ranging from construction to manufacturing can benefit from these specialized cylinders, ensuring that their hydraulic systems serve their intended purpose effectively. As technology continues to advance, the demand for customized hydraulic solutions will likely grow, driving further innovation in design and functionality. Whether you're looking to boost performance, extend the life of your equipment, or improve overall operational efficiency, custom priming hydraulic cylinders offer a compelling solution tailored to your needs.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025