Oct . 11, 2024 19:07 Back to list

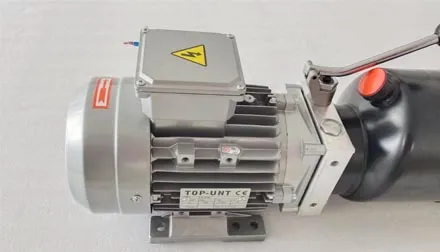

custom hydraulic valve cylinder

Custom Hydraulic Valve Cylinders A Comprehensive Overview

Hydraulic systems are pivotal in various industries, serving functions that range from heavy lifting to precise control in manufacturing. At the heart of many of these systems lies the hydraulic valve cylinder, a component that ensures the efficient operation of hydraulic machinery. When standard solutions do not meet specific requirements, custom hydraulic valve cylinders offer a tailored approach, enabling businesses to optimize their operations for unique applications.

A hydraulic valve cylinder operates by controlling the flow and pressure of hydraulic fluid within a system. It serves as a vital link that governs the performance of hydraulic actuators, such as cylinders and motors. The ability to customize these valves means manufacturers can take into account the unique specifications and demands of their machinery, ultimately leading to enhanced efficiency and productivity.

Custom hydraulic valve cylinders are designed to cater to a vast array of industries, including construction, automotive, aerospace, and even renewable energy sectors. One of the primary reasons for seeking customization is the diverse environments these valves must operate in—from extreme temperatures to high-pressure conditions. A well-designed custom valve can withstand these factors, ensuring reliability and longevity.

When developing a custom hydraulic valve cylinder, several considerations come into play. First and foremost, the intended application must be clearly understood. This encompasses everything from the type of fluid being used to the pressures the system will encounter. Furthermore, the size and configuration of the valve must be tailored to fit seamlessly within the existing hydraulic setup.

custom hydraulic valve cylinder

Another critical aspect is the materials used in the construction of the valve. Depending on the application, options may range from standard metals to specialized alloys that provide enhanced resistance to corrosion and wear. This choice can significantly affect the performance and durability of the hydraulic valve cylinder, ensuring it meets the operational demands of its environment.

Moreover, the design process typically involves collaboration between engineers, manufacturers, and end-users. This collaboration ensures that the final product not only meets technical specifications but also aligns with budgetary constraints and project timelines. Advanced technologies such as Computer-Aided Design (CAD) and 3D printing may be employed to create precise prototypes, allowing for iterative testing and modifications before full-scale production.

The benefits of custom hydraulic valve cylinders extend beyond mere functionality; they also contribute to overall system efficiency. By optimizing the hydraulic flow and pressure, businesses can minimize energy consumption and reduce the wear and tear on other components. This translates to lower operating costs and a reduced carbon footprint, aligning with sustainability goals increasingly recognized in today's industrial landscape.

In conclusion, custom hydraulic valve cylinders play a crucial role in enhancing the performance and reliability of hydraulic systems across various industries. Their tailored design ensures that they meet the specific needs of applications, providing businesses with the tools necessary to operate efficiently and effectively. As technology advances and industries evolve, the demand for customized solutions will continue to grow, solidifying the importance of custom hydraulic valve cylinders in modern engineering.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025