Nov . 19, 2024 01:28 Back to list

Tailored Hydraulic Oil Cylinders for Enhanced Performance and Reliability in Various Applications

Custom Hydraulic Oil Cylinders Enhancing Efficiency and Performance in Various Industries

Hydraulic systems are the backbone of many modern industrial processes, providing the power needed for machinery to operate effectively. At the heart of these systems is the hydraulic oil cylinder, a crucial component responsible for converting hydraulic energy into mechanical energy. When standard solutions don't meet the specific demands of certain applications, the need for custom hydraulic oil cylinders arises. This article explores the importance, benefits, and applications of custom hydraulic oil cylinders across different industries.

Understanding Hydraulic Oil Cylinders

A hydraulic oil cylinder consists of a cylinder barrel, a piston, and the hydraulic fluid that fills the chamber. When pressurized hydraulic fluid enters the cylinder, it causes the piston to move, creating linear motion that can be harnessed for various applications. The versatility of hydraulic cylinders makes them ideal for tasks ranging from lifting heavy loads in construction to precise movements in manufacturing processes.

The Need for Customization

Not all applications are the same; hence, one-size-fits-all hydraulic cylinders may not deliver the performance or reliability required for specialized tasks. Custom hydraulic oil cylinders are designed to meet specific requirements in terms of size, shape, capacity, and functionality. Factors such as stroke length, bore size, mounting options, and handling of extreme pressures and temperatures must be considered to ensure optimal performance.

Industries like aerospace, automotive, manufacturing, and construction often face unique challenges that necessitate the use of customized solutions. For instance, in the aerospace sector, components need to be lightweight while still providing the structural integrity to handle intense pressure. A standard hydraulic cylinder may not meet these stringent requirements, thereby emphasizing the need for customized solutions.

Benefits of Custom Hydraulic Oil Cylinders

1. Tailored Performance Custom cylinders can be engineered to deliver precise performance characteristics, ensuring they meet the specific needs of an application. This capability can result in increased efficiency and productivity.

2. Enhanced Durability By using materials and designs tailored to the operating environment, custom hydraulic cylinders can exhibit improved resistance to wear, corrosion, and extreme temperatures, thereby extending their lifespan.

3. Space Efficiency Custom cylinders can be designed to fit within the specific geometric constraints of machinery, optimizing space utilization. This feature is particularly beneficial in compact machinery and specialized equipment where every inch counts.

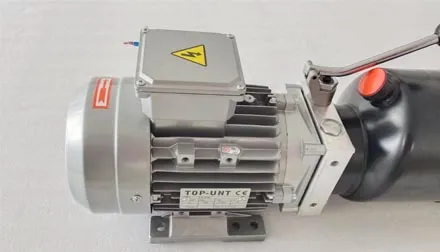

custom hydraulic oil cylinder

4. Improved Safety By customizing cylinders to better handle the forces and conditions encountered in specific applications, manufacturers can enhance the overall safety of the system, reducing the likelihood of failure.

5. Cost-Effectiveness Although custom solutions may require a higher initial investment, their increased efficiency and longevity can lead to significant cost savings over time. Lower maintenance costs and reduced downtime due to failures contribute to a more economical overall system.

Applications Across Industries

Custom hydraulic oil cylinders find applications across a vast array of industries

- Construction Used in machinery like excavators, cranes, and tractors, customized cylinders can enhance lifting capabilities and maneuverability.

- Manufacturing In assembly lines and automated processes, custom cylinders can improve precision and speed, facilitating better production outcomes.

- Aerospace Lightweight custom cylinders are crucial in aircraft systems, especially in landing gears and control mechanisms.

- Marine Customized hydraulic systems are essential for operating ship steering, cargo handling, and hydraulic lifts on vessels.

Conclusion

Custom hydraulic oil cylinders play a vital role in optimizing the performance of hydraulic systems across various industries. By addressing the specific needs of equipment and applications, these tailored solutions provide enhanced efficiency, durability, and safety. As industries continue to evolve and face new challenges, the demand for custom hydraulic solutions will only increase, paving the way for innovation and progress in hydraulic engineering. Investing in custom hydraulic oil cylinders is not just about meeting current needs, but also about preparing for future requirements in an ever-changing industrial landscape.

-

Premium Car Tailgate Power Units Reliable OEM Solutions

NewsMay.31,2025

-

China's Premium Hydraulic Cylinders Superior Power & ISO-Certified Force

NewsMay.31,2025

-

Boarding Axle Power Units Trusted Manufacturer & Supplier

NewsMay.30,2025

-

Custom Automotive Lift Power Units High-Performance & Durable Solutions

NewsMay.30,2025

-

China Balanced Hydraulic Cylinder Manufacturer High-Performance & Durable Solutions

NewsMay.30,2025

-

Wrecker Hydraulic Cylinders Heavy-Duty & Custom Solutions

NewsMay.29,2025