Nov . 14, 2024 02:38 Back to list

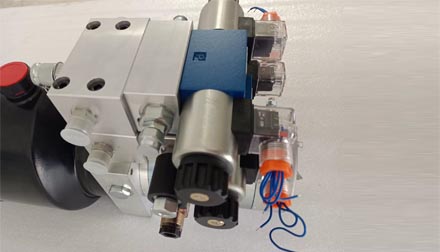

custom hydraulic damper cylinder

Understanding Custom Hydraulic Damper Cylinders

Hydraulic dampers play a crucial role in various applications where the control of motion and energy dissipation is essential. Among these devices, custom hydraulic damper cylinders are specially designed to meet unique specifications and requirements of different industries. This article delves into what custom hydraulic damper cylinders are, their applications, benefits, and considerations for design and manufacturing.

What is a Hydraulic Damper Cylinder?

A hydraulic damper cylinder is a device that uses hydraulic fluid to absorb and dissipate energy from moving parts. It serves to reduce vibration and oscillation, contributing to the stability and comfort of machinery and vehicles. Unlike standard dampers, custom hydraulic damper cylinders are tailored to specific parameters such as size, stroke length, pressure capacity, and damping characteristics. This customization ensures that the damper perfectly fits the application’s needs.

The Significance of Customization

One of the main advantages of custom hydraulic damper cylinders is their adaptability. Each application may require different damping rates, mounting configurations, and operational parameters. For instance, in the automotive industry, custom dampers are often used in suspension systems to enhance ride quality and handling. In industrial machinery, they can be used to minimize shock loads and vibrations that may cause wear and tear.

By utilizing custom solutions, manufacturers can significantly enhance the performance and reliability of their products. Custom hydraulic dampers can also lead to improved safety, reduced maintenance costs, and increased lifespan of the machinery they support.

Applications

Custom hydraulic damper cylinders find applications across various sectors, including

1. Automotive Industry In vehicles, custom dampers are vital for controlling suspension systems, ensuring a smooth ride, and improving handling in various driving conditions.

3. Construction and Heavy Equipment Custom dampers enhance stability and reduce vibrations in heavy machinery, leading to better performance and operator comfort.

custom hydraulic damper cylinder

4. Industrial Machinery In manufacturing settings, hydraulic dampers are crucial for machinery that experiences repetitive motion, helping to prolong the life of the equipment and reduce downtime due to repairs.

5. Marine Applications Hydraulic dampers are also featured in boats and ships to minimize the effects of waves and improve overall stability at sea.

Factors to Consider When Designing Custom Hydraulic Dampers

When designing a custom hydraulic damper cylinder, several factors need careful consideration

1. Operational Requirements Establishing the requirements for stroke length, load capacity, and damping characteristics helps in formulating the right specifications for the application.

2. Environmental Conditions Hydraulic dampers will be exposed to various environmental factors, such as temperature, pressure, and potential contaminants. The materials used should withstand these conditions to ensure durability.

3. Integration with Existing Systems Designers must consider how the custom damper will integrate with existing systems. This includes the mounting configuration and how it interacts with other components.

4. Cost-Effectiveness While customization may involve higher initial costs, it is essential to evaluate the long-term benefits, including reduced maintenance and improved performance, which can justify the investment.

5. Testing and Validation Once designed, comprehensive testing is crucial to verify that the damper meets the specified performance criteria. This phase may involve simulations and physical testing under controlled conditions.

Conclusion

Custom hydraulic damper cylinders serve an essential function in a multitude of industries by controlling motion and mitigating vibrations. Their specialized design caters to the unique demands of different applications, leading to better performance, enhanced safety, and increased reliability. By considering key factors in their design and manufacturing, businesses can ensure they achieve the optimum functionality from their hydraulic dampers. As industries continue to evolve, the demand for customized solutions will only increase, driving innovations in hydraulic technologies.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025