Sep . 29, 2024 09:15 Back to list

Tailored Sealing Solutions for Hydraulic Cylinders to Enhance Performance and Durability

Custom Hydraulic Cylinder Seals Enhancing Performance and Longevity

Hydraulic systems play a critical role in a variety of industrial and automotive applications, from manufacturing equipment to heavy machinery. At the heart of these systems are hydraulic cylinders, which rely on effective sealing to maintain pressure and prevent fluid leaks. This is where custom hydraulic cylinder seals come into play, designed to meet specific requirements and enhance the performance and longevity of hydraulic cylinders.

The Importance of Seals in Hydraulic Systems

Hydraulic cylinders operate by converting hydraulic energy into mechanical work. This process necessitates the containment of hydraulic fluid, which is vital for creating the pressure needed for operation. A properly sealed hydraulic cylinder is essential to prevent fluid leaking, which can result in operational inefficiencies, increased maintenance costs, and, in severe cases, catastrophic system failure. Therefore, the design and material selection of hydraulic cylinder seals are paramount to the overall performance of the hydraulic system.

Customized Seals Why Standard Solutions May Not Suffice

While off-the-shelf seals may work for standard applications, many hydraulic systems have unique requirements that standard solutions cannot adequately address. Factors such as operating pressure, temperature fluctuations, fluid compatibility, and environmental conditions necessitate custom solutions. Options like specialized profiles, materials, and sizes mean that custom seals can be engineered to fit precisely within the hydraulic cylinder, offering optimal sealing performance and durability.

For example, in high-pressure environments, seals must be designed to withstand intense forces without compromising their integrity. Similarly, if a hydraulic system operates in extreme temperatures, the material must retain its flexibility and strength even under thermal stress. Custom seals can be engineered from a range of materials, including polyurethane, fluorocarbon, and nitrile rubber, each possessing unique properties that can be leveraged based on specific operational conditions.

Enhanced Performance and Reliability

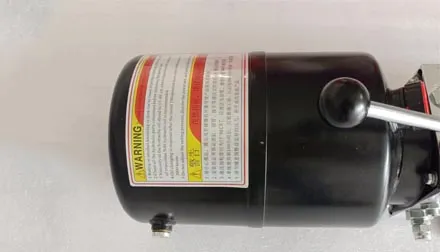

custom hydraulic cylinder seal

One of the primary benefits of custom hydraulic cylinder seals is the enhanced performance they deliver. Precision-engineered seals ensure a snug fit within the cylinder, which minimizes the potential for leakage and maximizes the efficiency of the hydraulic system. This results in smoother operation, reduced energy consumption, and overall improved productivity. Moreover, with fewer leaks, there is less environmental contamination, contributing to compliance with environmental regulations.

Custom seals also improve the longevity of hydraulic cylinders. By reducing wear and tear caused by inadequate sealing and friction, these seals help extend the lifecycle of the cylinder itself. This can lead to lower maintenance costs and less frequent replacements, ultimately providing a better return on investment for businesses that rely heavily on hydraulic machinery.

Designing Custom Seals The Process

The process of designing custom hydraulic cylinder seals typically involves close collaboration between engineers and manufacturers. It starts with an in-depth analysis of the specific demands of the application, followed by material selection based on compatibility and mechanical properties. Prototyping may be carried out, allowing for adjustments before settling on the final design.

Furthermore, advancements in technology, such as computer-aided design (CAD) tools, enable more precise modeling of seals, ensuring a perfect fit and function. With rapid prototyping, manufacturers can quickly test and refine their designs, reducing lead times and expediting production.

Conclusion

In the realm of hydraulic systems, the importance of effective sealing cannot be overstated. Custom hydraulic cylinder seals offer tailored solutions that boost performance, enhance reliability, and improve the lifespan of hydraulic cylinders. By investing in custom sealing solutions, businesses can ensure their hydraulic systems operate at peak efficiency, ultimately leading to greater productivity and minimized operational costs. Whether for high-pressure environments, extreme temperatures, or harsh substances, custom seals are a critical component that provides the reliability and efficiency modern hydraulic systems demand.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025