Oct . 16, 2024 12:44 Back to list

Understanding Hydraulic Cylinder Forces and Their Custom Applications

Understanding Custom Force in Hydraulic Cylinders

Hydraulic cylinders play a vital role in various industrial applications, providing the necessary force and movement to execute tasks ranging from lifting heavy loads to precision machining. The concept of custom force in hydraulic cylinders revolves around the ability to design and modify these cylinders to meet specific requirements, ensuring optimal performance in diverse scenarios.

The Basics of Hydraulic Cylinders

At its core, a hydraulic cylinder operates using pressurized fluid to create linear motion. The key components of a hydraulic cylinder include the cylinder barrel, piston, rod, and seals. When hydraulic fluid enters one side of the piston, it generates a force that moves the piston within the cylinder barrel. The amount of force produced is determined by the fluid pressure and the surface area of the piston.

Customizing the Force

The term custom force refers to the ability to tailor the force output of hydraulic cylinders according to the distinct needs of a project. Several factors can affect the required force, including the weight of the load, the speed of operation, and the specific application. Customizing the dimensions of the hydraulic cylinder—such as the diameter of the piston and the stroke length—can significantly influence the force it generates.

For example, in applications where high lifting capabilities are needed, such as in construction equipment or manufacturing machinery, the cylinder can be designed with a larger diameter piston to increase the force output. Conversely, in applications requiring more finesse and control, a smaller diameter piston may be appropriate, allowing for precise movements.

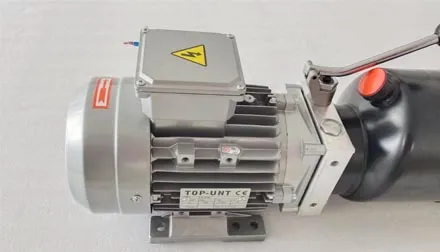

custom force in hydraulic cylinder

Importance of Pressure Ratings

Another crucial aspect of customizing force in hydraulic cylinders is understanding pressure ratings. The maximum operating pressure of the hydraulic system plays an integral role in determining the cylinder's effectiveness. By choosing components that can withstand higher pressures, manufacturers can increase the performance capacity of hydraulic cylinders. Thus, custom force designs must consider both the fluid dynamics involved and the physical constraints of the materials used.

Applications of Custom Hydraulic Cylinders

Custom hydraulic cylinders are widely used across various industries, including automotive, aerospace, marine, and construction. In the automotive industry, hydraulic cylinders are often used in assembly lines for tasks such as lifting vehicles or adjusting components during the manufacturing process. In aerospace, they play a critical role in the operation of landing gears and cargo doors.

Construction equipment, like excavators and bulldozers, relies heavily on hydraulic systems to operate effectively. Custom forces are essential in these scenarios, as they enable operators to lift and move heavy materials safely and efficiently. Furthermore, hydraulic cylinders used in marine applications, such as stabilizers and control systems, benefit from custom designs tailored to withstand harsh marine environments.

Conclusion

In conclusion, custom force in hydraulic cylinders is a fundamental concept that enhances the flexibility and efficiency of hydraulic systems across numerous applications. By understanding how to manipulate the design, pressure ratings, and operational parameters, engineers can create hydraulic cylinders that are not only powerful but also precisely matched to the unique demands of each task. As technology continues to advance, the potential for customized hydraulic solutions will likely expand, leading to increased functionality and improved outcomes in many industries. Whether it's lifting, pushing, or controlling machinery, the importance of custom hydraulic cylinders cannot be overstated, marking them as crucial components in modern engineering.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025