Oct . 21, 2024 18:09 Back to list

Custom Hydraulic Cylinders for Excavators Designed for Enhanced Performance and Durability

Custom Excavator Hydraulic Cylinders Enhancing Performance and Efficiency

In the world of heavy machinery, excavators play a vital role in various construction and earthmoving projects. Central to their functionality are hydraulic cylinders, which convert hydraulic energy into mechanical work. This ensures powerful movement and control for various attachments, making excavators indispensable in industries such as construction, mining, and landscaping. The need for custom excavator hydraulic cylinders has surged as businesses seek to optimize performance, enhance operational efficiency, and address specific application requirements.

Understanding Hydraulic Cylinders

Hydraulic cylinders function as the muscles of an excavator, providing the force required to lift heavy loads, rotate the arm, and operate various attachments. Typically, a hydraulic cylinder consists of a cylinder barrel, a piston, and end fittings, which are all designed to withstand extreme pressures and harsh environments. Custom hydraulic cylinders are tailored to meet the specific demands of projects and machinery, accounting for factors such as load capacity, stroke length, mounting styles, and required materials.

The Importance of Customization

Each construction project presents unique challenges, and standardized hydraulic cylinders may not always suffice. Customization offers numerous advantages

1. Tailored Specifications Custom hydraulic cylinders can be designed based on specific performance metrics, ensuring that they meet the exact requirements of the excavator's operational tasks. This can include dimensions, stroke length, and pressure ratings, allowing for optimized performance in demanding situations.

2. Improved Efficiency By selecting materials and designs that match the operating environment, custom cylinders can enhance the overall efficiency of the excavator. Optimized hydraulic systems minimize energy consumption and reduce the risk of equipment failure, leading to lower operating costs.

3. Increased Longevity and Durability Custom hydraulic cylinders can be constructed from high-quality materials that improve their resistance to wear, corrosion, and environmental challenges. This results in a longer lifespan and reduced maintenance needs, crucial for businesses that rely on heavy machinery for profitability.

4. Enhanced Performance Custom cylinders can accommodate specialized functions or attachments that standard models cannot handle effectively. Whether it's greater lifting capacities or unique angles of operation, customization ensures that excavators can perform a wider range of tasks with precision and power.

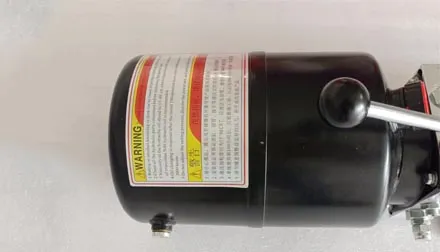

custom excavator hydraulic cylinder

The Process of Customization

The process of creating custom hydraulic cylinders involves several stages

1. Needs Assessment Engaging with clients to understand their specific requirements and the conditions under which the cylinders will operate is critical. Factors such as load size, speed, and environmental conditions must be considered.

2. Design and Engineering Highly skilled engineers use advanced computer-aided design (CAD) software to create detailed specifications. This stage includes calculations for stress, load, and pressure to ensure reliable performance.

3. Material Selection The choice of materials is fundamental to the durability and efficiency of hydraulic cylinders. Options may include high-strength steels, aluminum, or special coatings to enhance wear resistance.

4. Manufacturing After the design is finalized, the manufacturing process begins. This involves precision machining, welding, and assembling components to stringent quality standards.

5. Testing and Quality Assurance Rigorously testing the custom cylinders under various conditions ensures they meet performance expectations. Quality assurance processes verify adherence to industry standards and client specifications.

Conclusion

In conclusion, custom excavator hydraulic cylinders represent a significant advancement in heavy machinery performance. By providing tailored solutions that enhance efficiency, durability, and overall functionality, businesses can increase their productivity and reduce operational costs. As industries continue to evolve, the demand for custom hydraulic solutions will undoubtedly grow, reflecting a trend towards more specialized and efficient equipment in the construction and earthmoving sectors. Embracing customization not only empowers businesses to conquer unique challenges but also paves the way for innovation in hydraulic technology and engineering excellence.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025