Nov . 16, 2024 18:42 Back to list

custom double hydraulic cylinder

Understanding Custom Double Hydraulic Cylinders

Hydraulic cylinders are essential components in various machines and equipment used across industries. Among them, custom double hydraulic cylinders stand out due to their versatility and adaptability to specific applications. This article delves into the intricacies of custom double hydraulic cylinders, exploring their construction, functionality, advantages, and applications.

What is a Double Hydraulic Cylinder?

A double hydraulic cylinder operates with hydraulic fluid to produce linear motion. Unlike single-acting cylinders that only push in one direction, double hydraulic cylinders can pull and push, effectively doubling their functionality. A distinguishing feature of double cylinders is that they usually have two rods one for extending the cylinder and the other for retracting it. This mechanism creates a well-rounded system capable of handling varying forces and loads.

Customization Why It Matters

Custom double hydraulic cylinders are designed to meet specific needs that standard cylinders may not fulfill. Customization allows for alterations in dimensions, pressure ratings, materials, and additional features, making them ideal for unique applications. Whether the requirement involves a particular stroke length, rod diameter, or even specialized seals to withstand unique environmental conditions, a custom solution can enhance performance and longevity.

Construction and Design

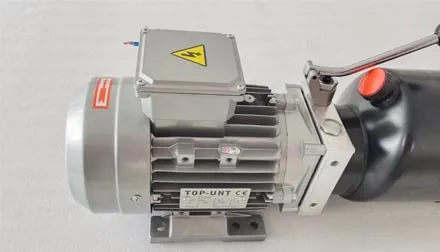

The construction of a double hydraulic cylinder typically includes several key components the cylinder barrel, piston, rods, seals, and end caps. Custom designs may incorporate advanced materials like high-strength alloys, which are essential for high-pressure environments. Additionally, the design must account for factors such as fluid dynamics, load capacity, and operating conditions to ensure reliability and efficiency. Engineers often use computer-aided design (CAD) tools to simulate performance and optimize the design before physical production.

custom double hydraulic cylinder

Advantages of Custom Double Hydraulic Cylinders

Custom double hydraulic cylinders offer several significant advantages over standard hydraulic cylinders. Firstly, they can be tailored to meet specific performance requirements, which enhances operational efficiency. For industries requiring specialized machinery, having a custom cylinder can reduce downtime and maintenance costs over time.

Secondly, they often exhibit improved reliability and safety. Custom cylinders are designed with the intended use in mind, which means potential failure points can be identified and addressed during the design phase, leading to a lower risk of malfunction during operation. This is particularly crucial in industries such as construction, manufacturing, and automotive, where safety is paramount.

Lastly, custom double hydraulic cylinders can be designed for improved energy efficiency. By creating systems that perfectly match the load requirements, unnecessary energy consumption can be minimized, contributing to a more sustainable operation.

Applications in Various Industries

The applications of custom double hydraulic cylinders are extensive and span various sectors. In construction, these cylinders are frequently used in construction equipment such as excavators and bulldozers, where precise control over heavy loads is essential. In manufacturing, they facilitate automation processes and assembly lines, often in robotics applications where accurate and powerful motion is required. Furthermore, in the aerospace industry, custom cylinders may be used in landing gear mechanisms and actuation systems, where reliability and weight savings are critical.

Conclusion

In conclusion, custom double hydraulic cylinders are indispensable components in many industrial applications. Their ability to be tailored for specific needs, coupled with their efficiency and reliability, make them a valuable asset across various sectors. As industries continue to evolve and demands for specialized machinery increase, the role of custom hydraulic solutions will remain vital, ensuring that they can meet the diverse needs of modern engineering challenges.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025