Dec . 11, 2024 21:19 Back to list

custom changing seals in hydraulic cylinder

Custom Changing Seals in Hydraulic Cylinders

Hydraulic cylinders are critical components in a wide range of machinery, from industrial equipment to construction vehicles. They convert hydraulic energy into mechanical force, enabling movement and handling of heavy loads with precision and efficiency. However, the performance and reliability of hydraulic cylinders largely depend on the seals used within them. Custom changing seals have emerged as a solution to enhance the efficiency and longevity of these systems. This article explores the importance of custom seals, their benefits, and consideration factors for their implementation in hydraulic cylinders.

Why Seals Matter in Hydraulic Cylinders

Seals are essential for preventing fluid leakage and protecting internal components from contaminants. In hydraulic systems, where high pressures and various fluids are involved, the integrity of seals is paramount. A failure in the seals can lead to hydraulic fluid loss, inefficiency in operation, increased operational costs, and even catastrophic equipment failure. Therefore, selecting the right seals for hydraulic cylinders directly correlates with overall system performance.

The Case for Custom Seals

While standard seals can meet the demands of many applications, custom seals provide tailored solutions that can significantly enhance performance. Custom seals are designed to accommodate specific operational conditions, such as unique pressures, temperatures, and fluid compositions. This customization ensures that the seals effectively mitigate wear and tear, leading to improved longevity and reliability of the hydraulic cylinders.

One of the main advantages of custom seals is the ability to adapt to the unique dimensions and configurations of different hydraulic cylinder designs. Manufacturers of hydraulic cylinders can leverage custom seals to enhance efficiency, as these seals often provide a better fit and performance compared to standard options. Furthermore, they can be designed to withstand particular challenges, such as high temperatures, aggressive fluids, or extreme pressures prevalent in demanding applications.

Benefits of Custom Changing Seals

1. Enhanced Performance Custom seals can be engineered to optimize the dynamic performance of hydraulic cylinders. Their precise fit helps minimize friction and wear, enabling smoother operation and extending the lifespan of the equipment.

2. Improved Reliability By addressing specific sealing needs, custom seals minimize the risk of leaks and contamination, thus enhancing the reliability of hydraulic systems. This is particularly important in industries where equipment failure can lead to costly downtimes or safety hazards.

3. Cost Efficiency Although custom seals may have a higher initial cost, they can lead to significant savings over time. By reducing the frequency of seal replacements and the associated maintenance costs, custom seals can improve the total cost of ownership for hydraulic systems.

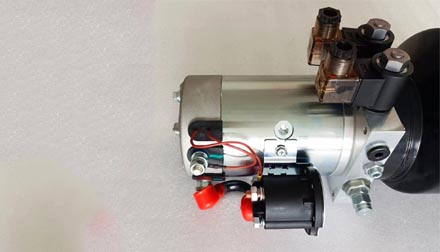

custom changing seals in hydraulic cylinder

4. Material Flexibility Custom seals can be made from various materials tailored to the conditions they will face. Whether it’s high-temperature elastomers or robust metal seals, the right material can enhance performance and durability.

5. Design Innovation With advances in engineering and materials technology, custom seals can incorporate innovative designs that further enhance their effectiveness. Features such as improved lip geometry or integrated wear rings can be included to meet specific operational requirements.

Factors to Consider When Implementing Custom Seals

When considering custom changing seals for hydraulic cylinders, several factors must be taken into account

- Operational Environment Understand the pressures, temperatures, and types of fluids the seals will encounter.

- Cylinder Design Analyze the specific dimensions and requirements of the hydraulic cylinder to ensure a perfect fit.

- Material Selection Choose materials that can withstand the operational challenge without compromising performance.

- Supplier Capability Work with reputable seal manufacturers who can provide custom solutions backed by expertise and experience.

- Cost-Benefit Analysis Evaluate the long-term benefits of custom seals against their initial cost to make informed decisions.

Conclusion

Custom changing seals play a vital role in enhancing the performance and reliability of hydraulic cylinders in various applications. By catering to specific operational challenges and providing tailored solutions, these seals help improve efficiency, reduce maintenance costs, and extend the life of hydraulic systems. As industries continue to evolve, the demand for advanced sealing solutions will grow, making a strong case for the investment in custom seals for ensuring optimal hydraulic performance.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025