Aug . 14, 2024 00:49 Back to list

Custom Hydraulic Cylinder Solutions for Rotary Lifts Designed for Enhanced Performance and Reliability

Custom Rotary Lift Hydraulic Cylinder Enhancing Efficiency and Versatility in Lifting Applications

In the realm of machinery and engineering, hydraulic cylinders play a crucial role in powering and facilitating various lifting operations. Among these, custom rotary lift hydraulic cylinders stand out for their ability to provide precision, strength, and adaptability for a variety of industrial applications. Understanding their design, functionality, and benefits is essential for businesses looking to enhance their operational efficiency.

What is a Hydraulic Cylinder?

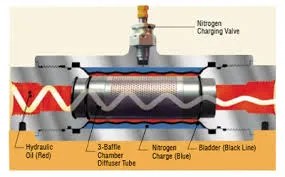

At its core, a hydraulic cylinder is a mechanical actuator that converts hydraulic pressure into linear motion. By utilizing the incompressible nature of hydraulic fluid, these cylinders generate substantial force and can move heavy loads with minimal effort. A rotary lift hydraulic cylinder, in particular, is designed to provide rotational movement in addition to the standard lifting capabilities, making it ideal for applications requiring both vertical and horizontal motion.

Customization Tailored Solutions for Unique Needs

One of the most significant advantages of custom rotary lift hydraulic cylinders is their adaptability. Different industries have varying requirements based on the specific tasks they perform. For example, automotive service centers need robust lifting solutions for vehicles, while manufacturing facilities may require cylinders for machinery assembly and material handling.

Custom hydraulic cylinders can be designed to meet specific load capacities, stroke lengths, and mounting configurations, ensuring seamless integration into existing systems. Engineers can select materials, coatings, and seal types that are best suited for the working conditions, whether it’s exposure to corrosive substances, extreme temperatures, or heavy loads.

Benefits of Rotary Lift Hydraulic Cylinders

custom rotary lift hydraulic cylinder

1. Increased Precision and Control Custom rotary lift hydraulic cylinders provide enhanced control over movements, allowing for precise positioning of heavy loads. This is particularly important in applications where accuracy is critical, such as in assembly lines or when maneuvering sensitive equipment.

2. Space Efficiency The compact design of rotary lift hydraulic cylinders allows them to fit into tighter spaces compared to traditional lifting mechanisms. This space-saving feature is advantageous for urban and industrial settings where real estate is limited.

3. Improved Safety Hydraulic systems can be engineered with safety features such as overload protection, preventing accidents from lifting beyond the cylinder's capacity. This not only protects the equipment but also ensures the safety of the operators.

4. Versatility The ability to provide both lifting and rotary motion enables these cylinders to be used in diverse applications, from automotive lifts and conveyor systems to construction equipment and robotics. Their versatility makes them an excellent investment for companies looking to streamline multiple processes.

5. Durability and Reliability Custom hydraulic cylinders are built to withstand rigorous working conditions. With high-quality materials and precision engineering, they boast longer service lives and reduced maintenance needs, resulting in cost savings for businesses.

Conclusion

As industries evolve and demand for efficient lifting solutions rises, custom rotary lift hydraulic cylinders emerge as vital tools that can enhance productivity and safety. Their unique design allows for a combination of lifting and rotational movements, providing unmatched versatility in various applications. By investing in tailored hydraulic solutions, businesses can ensure they have the right equipment to meet their specific needs, ultimately leading to improved operational efficiency and a competitive edge in the market. Whether in automotive service, manufacturing, or construction, the importance of custom rotary lift hydraulic cylinders cannot be overstated, making them a key player in the future of lifting technology.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025