Sep . 22, 2024 04:34 Back to list

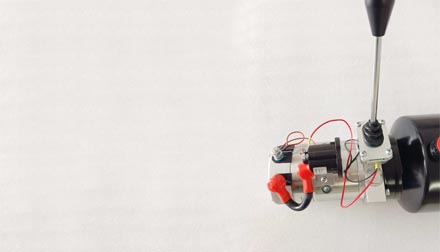

cross section of hydraulic cylinder manufacturer

The Importance of Cross Sections in Hydraulic Cylinder Manufacturing

Hydraulic cylinders are essential components in various machinery and applications, providing the force needed to handle heavy loads and perform powerful movements. One key aspect that influences the performance and efficiency of hydraulic cylinders is their cross-sectional design. This article explores the importance of cross-sectional shapes in hydraulic cylinder manufacturing and how they impact functionality, strength, and efficiency.

The cross section of a hydraulic cylinder refers to the shape of its internal and external structure when viewed in a perpendicular plane. Common shapes include circular, rectangular, and even custom profiles, depending on the application needs. Circular cross sections are the most prevalent, as they provide uniform strength and are efficient in handling pressure from the hydraulic fluid. This shape allows for even distribution of forces around the circumference, reducing the likelihood of material failure under load.

One of the critical functions of a hydraulic cylinder is to convert fluid pressure into mechanical energy. The cross-sectional area of the cylinder directly affects its force output. According to Pascal's principle, the force exerted by a hydraulic system is equal to the fluid pressure multiplied by the area of the piston. For instance, a larger cross-sectional area translates to greater force output for the same pressure. Therefore, optimizing cross-sectional dimensions is vital for achieving the desired performance in specific applications.

cross section of hydraulic cylinder manufacturer

Moreover, the choice of cross section influences the material used in the cylinder's construction. Manufacturers often select materials based on the cylinder's design and load requirements. For example, a rectangular or custom-designed cross section may require stronger materials to withstand stress concentrations and ensure durability. Innovative materials and manufacturing techniques are continually evolving, enabling manufacturers to create cross-sectional designs that minimize weight while maximizing strength.

In addition to strength and efficiency, the cross-section shape can also affect the cylinder's overall dimensions and installation requirements. For instance, a compact, rectangular profile may be more suitable for tight spaces in industrial machinery, while a circular shape may be needed for applications requiring robustness and reliability.

Lastly, the design of the hydraulic cylinder’s cross section must consider the overall system design, including connections and fluid dynamics. A well-designed cross section can enhance the flow characteristics of the hydraulic fluid, improving responsiveness and minimizing energy losses during operation.

In conclusion, the cross section of hydraulic cylinders plays a crucial role in their manufacturing, influencing performance, strength, and application suitability. As technology advances, manufacturers continue to innovate in design and materials, ensuring that hydraulic cylinders meet the demanding needs of modern machinery and industry. Understanding the importance of cross-sectional shapes will help engineers and designers optimize their systems for better efficiency and reliability.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025