Sep . 16, 2024 00:10 Back to list

Combined Hydraulic Cylinder - High Performance Hydraulic Solutions

Understanding Combined Hydraulic Cylinder Products Efficiency in Motion

In today’s fast-paced industrial landscape, the demand for efficient and versatile machinery is paramount. Among the most fundamental components driving this efficiency is the hydraulic cylinder. The combined hydraulic cylinder, in particular, has garnered attention for its innovative approach to enhancing performance in various applications.

A combined hydraulic cylinder is a sophisticated piece of engineering that integrates multiple functions into a single unit. Traditionally, hydraulic cylinders were employed for singular tasks, such as lifting or pushing. However, as industries strive for efficiency and space-saving solutions, the combined hydraulic cylinder emerges as a practical alternative, merging the functionality of several cylinders into one. This not only reduces the footprint of machinery but also simplifies the hydraulic system, minimizing potential points of failure.

The working principle of a combined hydraulic cylinder revolves around hydraulic fluid mechanics. By utilizing hydraulic fluid under pressure, these cylinders convert hydraulic energy into mechanical energy, enabling them to perform tasks with significant force. Typically, these products feature a dual-chamber design, allowing for both extension and retraction motions to occur seamlessly. This dual functionality can enhance operational flexibility, making them suitable for varied tasks within the same cycle.

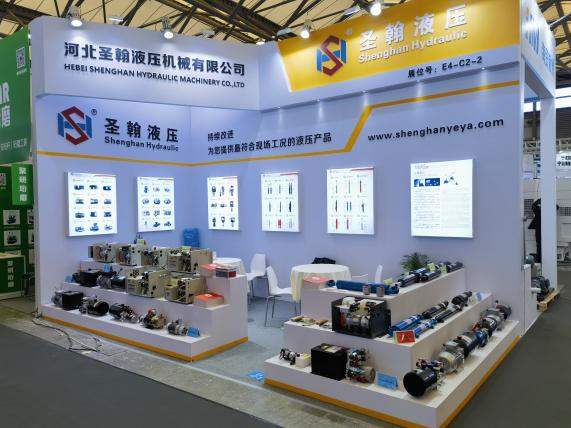

combined hydraulic cylinder product

One of the most notable advantages of combined hydraulic cylinders is their efficiency. By reducing the number of components needed for an operation, manufacturers can cut down on installation time, reduce maintenance needs, and ultimately decrease overall costs. Furthermore, the integration of multiple actions into a single cylinder minimizes power loss and improves cycle times, leading to higher productivity rates.

Applications for combined hydraulic cylinders are diverse. They are commonly found in construction equipment, such as excavators and loaders, where space is at a premium, and efficiency is crucial. Additionally, these cylinders are crucial in manufacturing processes, where precise control of movement is required. Their ability to handle significant weights while maintaining accuracy makes them an asset in assembly lines and other industrial environments.

In conclusion, the combined hydraulic cylinder represents a significant advancement in hydraulic technology, merging multiple functionalities into an efficient and compact design. Its ability to enhance productivity, reduce costs, and simplify operations makes it an invaluable component in numerous industrial applications. As industries continue to evolve and prioritize efficiency, the reliance on combined hydraulic cylinders is likely to grow, shaping the future of machinery and fluid power systems. Investing in this technology can provide businesses with a competitive edge, making it a worthwhile consideration for any operation seeking to optimize performance and reliability.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025