Nov . 08, 2024 00:10 Back to list

Hydraulic Cylinder Manufacturing for Column Load Applications

Understanding Column Load in Hydraulic Cylinder Factories

Hydraulic cylinders are vital components in various industrial applications, and their design and performance are significantly influenced by the concept of column load. Column load refers to the axial load that a hydraulic cylinder can support while maintaining structural integrity under operational conditions. Understanding this concept is essential for engineers and manufacturers in hydraulic cylinder factories to ensure safety, efficiency, and reliability in their products.

Basics of Hydraulic Cylinders

Hydraulic cylinders convert hydraulic energy into mechanical energy, generating linear motion. They consist of a cylinder barrel, piston, and end caps. Pressurized fluid enters the cylinder, pushing the piston, which in turn moves the attached load. The efficiency and effectiveness of hydraulic cylinders depend not only on their design but also on how well they can handle load conditions, particularly column loads.

Importance of Column Load

In a hydraulic cylinder, the column load can arise from the weight of the attached load, gravitational forces, and any external forces acting upon the cylinder. The ability of a cylinder to withstand these loads without buckling or failing is crucial for safety and operational performance. A cylinder that can't manage its column load risks catastrophic failure, leading to equipment damage, production downtime, and even endangerment of personnel.

Calculating Column Load

Engineers utilize various formulas and principles from mechanics to determine the maximum column load a hydraulic cylinder can support. The calculation considers factors such as

1. Material Properties The type of materials used in the cylinder's construction, including their yield strength and tensile strength, play a significant role in determining how much load the cylinder can support. 2. Geometric Dimensions The dimensions of the cylinder, particularly its diameter and length, significantly affect its ability to handle loads. A thicker and shorter cylinder is generally better at resisting buckling than a long and slender one.

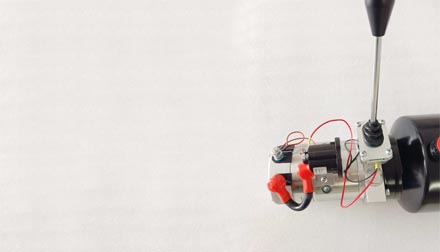

column load hydraulic cylinder factory

3. End Conditions The way the ends of the cylinder are fixed or supported affects its load-bearing capacity. Free, fixed, or pinned supports change the column's effective length and rigidity.

Design Considerations in Factories

In hydraulic cylinder factories, engineers must incorporate the concept of column load into their design phase. This can involve selecting appropriate materials and dimensions for the cylinders to ensure optimal performance under expected load conditions. Factories often employ computer-aided design (CAD) and finite element analysis (FEA) software to simulate performance under various loading scenarios, enabling them to make better-informed design choices.

Moreover, manufacturers must ensure strict quality control during production. Even small defects in material or fabrication can significantly impact the cylinder's ability to handle column loads, making rigorous testing and inspection processes essential.

Safety Standards and Regulations

To ensure that hydraulic cylinders meet necessary safety standards, regulatory bodies often impose guidelines that specify the testing and certification processes for these components. This includes assessments of column load capacity, fatigue testing, and failure analysis. Compliance with these regulations not only safeguards employees and equipment but also builds trust with customers who rely on these products for critical applications.

Conclusion

Column load is a fundamental concept that plays a crucial role in the design and manufacture of hydraulic cylinders. By understanding the intricacies of column load, manufacturers can create reliable and safe hydraulic systems that meet the needs of various industrial applications. As technology advances and industries evolve, the importance of precise calculations and design in relation to column loads will continue to grow, fostering a culture of safety and efficiency within hydraulic cylinder factories.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025