Dec . 10, 2024 05:23 Back to list

china rebuilding hydraulic cylinder

Rebuilding Hydraulic Cylinders in China A Vital Industry for Growth and Innovation

In recent years, China has emerged as a global leader in various industrial sectors, and the rebuilding of hydraulic cylinders is no exception. Hydraulic cylinders play a crucial role in hydraulic systems, providing the force necessary for the operation of machinery in construction, manufacturing, and automotive industries. Given their widespread use, the efficiency and longevity of these components are vital for the overall productivity of numerous sectors.

The Importance of Hydraulic Cylinder Rebuilding

Hydraulic cylinders are subject to wear and tear due to continuous operation and exposure to harsh working conditions. Rebuilding these cylinders becomes essential not only for maintaining equipment efficiency but also for reducing operational costs. A rebuilt hydraulic cylinder can restore lost functionality, ensuring machines run smoothly. In China, the rebuilding industry has flourished, driven by the need for durability and sustainability in manufacturing processes.

Economic Impact

The hydraulic cylinder rebuilding sector contributes significantly to China’s economy. By focusing on refurbishing rather than replacing these essential components, companies can save substantial resources while minimizing waste. This aligns with the country's environmental goals to adopt more sustainable manufacturing practices. Furthermore, the rebuilding industry provides numerous job opportunities, ranging from skilled engineers to factory workers, bolstering local economies.

Technological Advances in Rebuilding

China's focus on industrial innovation has led to significant advancements in technology used for rebuilding hydraulic cylinders. The incorporation of modern machinery and techniques, such as computer numerical control (CNC) machining and advanced welding technologies, allows for precise and efficient restoration processes. This technological progress not only improves the quality of rebuilt cylinders but also speeds up turnaround times, minimizing downtime for businesses that rely on hydraulic systems.

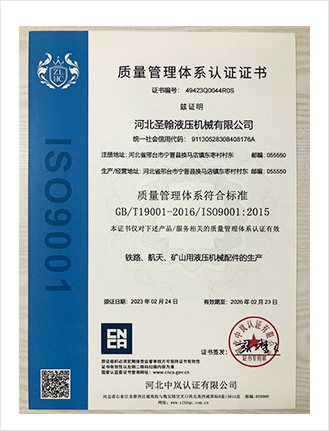

Quality Assurance and Standards

china rebuilding hydraulic cylinder

As the rebuilding industry grows, so does the emphasis on quality assurance and adherence to international standards. Chinese companies are increasingly implementing rigorous testing procedures to ensure that rebuilt cylinders meet global benchmarks. These standards include pressure testing, dimensional checks, and surface finish evaluations. By maintaining high-quality standards, Chinese manufacturers can compete in the global market, exporting their rebuilt hydraulic cylinders to countries around the world.

Challenges in the Rebuilding Industry

Despite its growth, the hydraulic cylinder rebuilding industry in China faces several challenges. The availability of skilled labor is a pressing issue, as the industry requires a workforce proficient in both traditional mechanical skills and modern technology. To address this, many companies are investing in training programs and partnerships with technical schools, ensuring that workers possess the necessary skills to thrive in an evolving landscape.

Additionally, as the demand for more advanced and specialized hydraulic systems increases, rebuilding processes must adapt. This requires ongoing research and development to innovate techniques and materials that enhance the performance of hydraulic cylinders.

Future Prospects

Looking ahead, the hydraulic cylinder rebuilding industry in China is poised for continued growth. With the rising trend of automation and smart manufacturing, the demand for efficient hydraulic systems will likely escalate. This presents an opportunity for the rebuilding sector to expand its services and offerings.

Moreover, as international markets demand sustainable practices, China's achievements in hydraulic cylinder rebuilding—balancing cost-effectiveness with ecological responsibility—position the country as a leader in the global market. Companies that can successfully blend innovation with quality assurance will undoubtedly thrive in this expanding field.

In conclusion, the rebuilding of hydraulic cylinders is not just a component of machinery maintenance; it is a dynamic industry reflecting China's commitment to growth and sustainability. Through technological advancements and a focus on quality, China is setting standards that will influence the hydraulic sector worldwide, ensuring that it remains at the forefront of industry innovation for years to come.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025