Nov . 10, 2024 18:45 Back to list

China's Hydraulic Trim Cylinder Solutions for Efficient Marine and Industrial Applications

Understanding China Hydraulic Trim Cylinders

Hydraulic trim cylinders are critical components in various marine applications and industrial machinery, providing essential functions such as lifting, lowering, and adjusting the tilt of equipment. In China, the manufacturing sector has seen significant advancements in hydraulic technology, leading to the production of highly efficient and reliable hydraulic trim cylinders. This article delves into the functionality, design, and the economic significance of hydraulic trim cylinders produced in China.

Functionality of Hydraulic Trim Cylinders

Hydraulic trim cylinders work by harnessing the power of hydraulic fluid, which generates force through confined liquid under pressure. In marine vessels, these cylinders are primarily used to adjust the angle of the boat's hull, ensuring optimal performance and stability. By altering the trim angle, operators can improve fuel efficiency, increase speed, and enhance overall seaworthiness. Beyond maritime applications, hydraulic trim cylinders are also utilized in construction equipment, agricultural machinery, and various industrial setups for tasks requiring precise movements and heavy lifting.

Design and Manufacturing in China

China has emerged as a leading manufacturer of hydraulic systems, including trim cylinders. The design of these cylinders often reflects a balance between strength, weight, and efficiency. Chinese manufacturers utilize modern engineering techniques and advanced materials such as high-strength steel and aluminum alloys. This not only enhances the durability of the cylinders but also mitigates issues such as corrosion and wear over time.

Manufacturing processes in China employ cutting-edge technology, including computer-numerical control (CNC) machining, hydraulic testing systems, and quality assurance protocols. These methodologies ensure that the hydraulic trim cylinders produced meet high standards of precision and performance. Additionally, many manufacturers are embracing automation, which leads to increased production capacity and reduced costs while maintaining quality.

Economic Significance

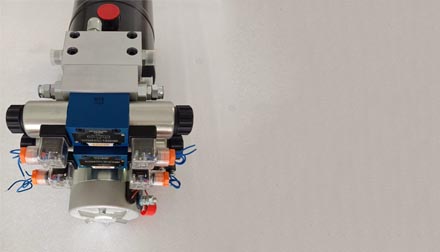

china hydraulic trim cylinder

The production of hydraulic trim cylinders in China plays a crucial role in the country’s economy. The hydraulic equipment market is vast, benefiting from both domestic demand and international exports. China’s robust manufacturing capabilities enable it to supply hydraulic components to various industries, thereby fostering economic growth and providing job opportunities.

Moreover, the demand for hydraulic trim cylinders is not confined to China. The global maritime industry, along with sectors such as agriculture and construction, increasingly relies on Chinese products due to their competitive pricing and quality. As countries expand their fleets and enhance their infrastructure, Chinese manufacturers are poised to service these markets effectively, showcasing the potential for continued growth.

Innovations and Future Trends

As the global focus shifts towards sustainability and efficiency, Chinese manufacturers are increasingly investing in research and development to innovate their hydraulic systems. Recent trends include the integration of smart technology into hydraulic trim cylinders, enabling real-time monitoring and remote operation capabilities. Such advancements can lead to enhanced efficiency, predictive maintenance, and reduced downtime, contributing to overall operational cost savings.

Moreover, the exploration of eco-friendly hydraulic fluids and recyclable materials for manufacturing processes reflects a response to environmental concerns. As stricter regulations emerge worldwide regarding emissions and waste management, the ability to adapt and innovate will be key for manufacturers to remain competitive.

Conclusion

In conclusion, hydraulic trim cylinders manufactured in China are pivotal to various industries due to their versatility, efficiency, and reliability. As the manufacturing landscape continues to evolve, the integration of advanced technologies and sustainable practices will likely shape the future of hydraulic systems. With a strong commitment to innovation and quality, Chinese manufacturers stand at the forefront of the global hydraulic equipment market, driving economic growth while addressing the increasing demands for efficiency and environmental responsibility. Understanding the significance of these components allows stakeholders to appreciate the vital role they play in ensuring the smooth operation of countless machines and vessels worldwide.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025