Dec . 05, 2024 16:55 Back to list

China Hydraulic Cab Tilt Cylinder Solutions for Enhanced Vehicle Performance and Stability

Understanding China Hydraulic Cab Tilt Cylinders

Hydraulic systems play a critical role in modern machinery, providing the necessary force and movement required in various applications, including construction equipment, automotive manufacturing, and agricultural machinery. Among these systems, the hydraulic cab tilt cylinder has garnered significant attention, particularly in the context of vehicles and equipment used in rugged environments, such as excavators, loaders, and trucks. This article explores the functionality, design, and advantages of hydraulic cab tilt cylinders, with a focus on their applications in the Chinese market.

What is a Hydraulic Cab Tilt Cylinder?

A hydraulic cab tilt cylinder is a hydraulic actuator designed to lift or lower the cab of a vehicle. This mechanism allows easier access to the engine and other components located under the cab. By tilting the cab, maintenance personnel can quickly perform routine inspections, repairs, and replacements without the need for extensive disassembly. In China, where construction and agricultural machinery are prevalent, the demand for efficient maintenance solutions has led to widespread adoption of hydraulic cab tilt systems.

Functionality and Design

The basic operation of a hydraulic cab tilt cylinder involves the conversion of hydraulic pressure into mechanical force. The cylinder consists of a piston, rod, and a cylinder housing filled with hydraulic fluid. When hydraulic fluid is pumped into the cylinder, it causes the piston to move, extending or retracting the rod. This process facilitates the smooth tilting of the cab.

One innovative aspect of the design is the incorporation of safety features, such as hydraulic locks and load-holding valves. These features prevent the cab from falling unexpectedly during maintenance, ensuring safety for operators and technicians alike. Moreover, the cylinder design is often tailored to meet specific requirements concerning stroke length, force capacity, and mounting dimensions, depending on the application.

Advantages of Hydraulic Cab Tilt Cylinders

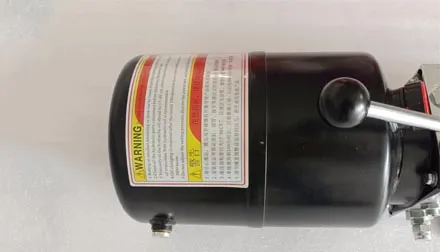

china hydraulic cab tilt cylinder

The benefits of using hydraulic cab tilt cylinders are manifold, making them a favored choice in the construction and agricultural sectors.

1. Ease of Maintenance As mentioned earlier, the primary advantage is the ease of access to engine components. This streamlines maintenance operations, reducing downtime and increasing productivity. For industries where time is money, this efficiency is crucial.

2. Compact Design Hydraulic cylinders can be designed to fit within tight spaces without compromising performance. This is particularly important in heavy machinery, where every millimeter counts.

3. Durability and Reliability Hydraulic systems are known for their robust performance under harsh conditions. The materials and engineering used in designing these cylinders ensure they withstand wear and tear, providing reliable service over an extended period.

4. Precision Control Hydraulic cab tilt systems allow for controlled tilting, enabling operators to position the cab at various angles as needed. This precision is vital for effective maintenance and reduces the risk of damaging internal components.

5. Widespread Adoption in China The rapid industrialization and growth of infrastructure in China have created a booming market for heavy machinery. As manufacturers and contractors seek efficient equipment, the demand for hydraulic cab tilt cylinders continues to rise.

Conclusion

In conclusion, hydraulic cab tilt cylinders represent a significant advancement in the field of machinery maintenance. Their ability to enhance accessibility and streamline service operations is invaluable, especially within the fast-paced environments of construction and agriculture in China. With ongoing innovations in hydraulic technology, we can expect to see further improvements in the design and functionality of cab tilt cylinders, continuing to support the evolving needs of the industry. As stakeholders in the machinery sector recognize the benefits of these systems, the future of hydraulic cab tilt cylinders appears robust and promising, revolutionizing maintenance practices and ultimately contributing to increased operational efficiency.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025