Oct . 13, 2024 18:43 Back to list

China's Hydraulic Cylinder for Heavy-Duty Applications with Double Stroke Mechanism

Understanding the China Double Stroke Hydraulic Cylinder

In the realm of hydraulic systems, the double stroke hydraulic cylinder stands out for its efficiency and versatility. Particularly prominent in China, this type of hydraulic cylinder has garnered attention across various industries due to its capability to produce high force output with minimal input. This article aims to elucidate the operational mechanics, applications, and advantages of double stroke hydraulic cylinders.

Operational Mechanics

At its core, a double stroke hydraulic cylinder operates using the principles of hydraulics, where pressurized fluid is utilized to exert force and produce motion. The fundamental innovation behind the double stroke design lies in its ability to extend and retract in two distinct strokes, providing greater movement and flexibility than traditional single-stroke cylinders.

Typically, a double stroke hydraulic cylinder consists of a cylindrical barrel, a piston, and ports for fluid entry and exit. When hydraulic fluid is pumped into the cylinder, the pressure moves the piston in one direction. By utilizing a simple change in fluid direction, the piston retracts, allowing for continuous operation without the need for external actuators. This back-and-forth motion is what gives the double stroke hydraulic cylinder its name and versatility in various applications.

Applications in Various Industries

The utility of double stroke hydraulic cylinders is evident in several sectors. In manufacturing, these cylinders are widely used in pressing, molding, and stamping operations. Their high force output makes them ideal for tasks that require significant force to shape materials efficiently.

In construction, double stroke hydraulic cylinders play a critical role in heavy equipment operation, such as excavators and loaders

. Their ability to handle heavy loads with precision allows for a more effective and safe work environment.china double stroke hydraulic cylinder

Moreover, in the automotive industry, these cylinders are commonly found in assembly lines where components must be precisely aligned and pressed together. The consistency and reliability of double stroke hydraulic cylinders ensure high-quality production standards.

Advantages of Double Stroke Hydraulic Cylinders

There are numerous advantages to employing double stroke hydraulic cylinders over traditional alternatives. Firstly, their ability to generate significant force with relatively small hydraulic inputs makes them incredibly efficient. This can lead to reduced operational costs and energy consumption, a vital consideration for businesses seeking sustainability.

Moreover, double stroke hydraulic cylinders exhibit enhanced durability and longevity due to their robust construction. With fewer moving parts than conventional cylinders, they are less prone to wear and tear, minimizing maintenance issues and downtime.

Additionally, their compact design allows them to fit in tight spaces, which is particularly advantageous in applications where space is at a premium. This versatility opens up opportunities in innovative engineering designs where compact yet powerful solutions are required.

Conclusion

The China double stroke hydraulic cylinder represents a significant advancement in the field of hydraulics, offering unmatched efficiency, versatility, and reliability. As industries continue to seek solutions that optimize productivity while conserving resources, the adoption and innovation surrounding double stroke hydraulic cylinders are likely to flourish. Whether in manufacturing, construction, or automotive applications, these hydraulic cylinders provide a critical solution for effective motion control, paving the way for future technological advancements in hydraulic systems.

-

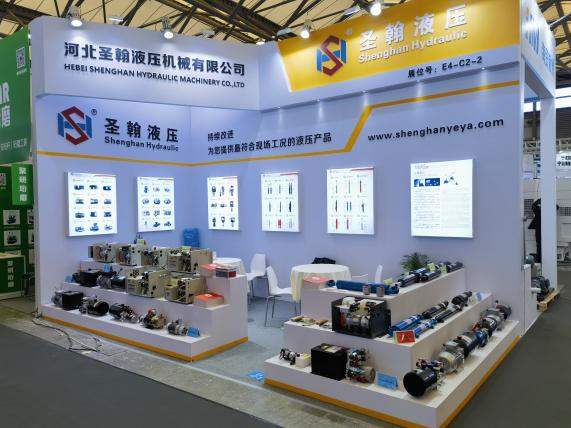

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025