Dec . 10, 2024 16:31 Back to list

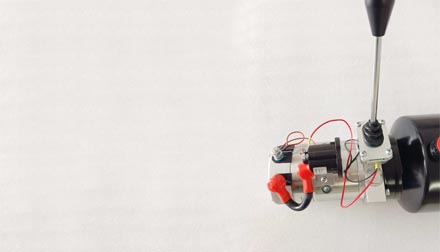

china bobcat hydraulic cylinder

The Role of Hydraulic Cylinders in Bobcat Equipment A Focus on China

The Bobcat brand is synonymous with reliability and versatility in the realm of compact machinery, and at the heart of many of its renowned products lies the hydraulic cylinder. These components play a crucial role in the operation of various Bobcat equipment, from mini excavators to skid-steer loaders. With a growing presence in China’s construction and agricultural sectors, understanding the significance of hydraulic cylinders in Bobcat machines can shed light on their contribution to efficient operations.

The Role of Hydraulic Cylinders in Bobcat Equipment A Focus on China

China's construction industry has experienced rapid growth in recent years, driving demand for reliable and robust machinery. Bobcat, recognized for its innovation and commitment to quality, has made significant inroads into this market. With various models tailored to meet the specific needs of Chinese consumers, the emphasis on hydraulic cylinders has become more pronounced. These cylinders are engineered to withstand the harsh conditions often encountered on construction sites, providing durability and efficiency that operators can depend on.

china bobcat hydraulic cylinder

The customization of hydraulic cylinders for Bobcat machinery is another important aspect. In China, the diverse range of construction projects, from urban infrastructure to rural agricultural tasks, necessitates equipment that can adapt to various challenges. Hydraulic cylinders in Bobcat machines can be tailored in terms of size, force output, and stroke length, ensuring that they meet the specific requirements of each task. This customizability not only enhances performance but also allows for improved efficiency and reduced operational costs.

Furthermore, advancements in hydraulic technology have played a pivotal role in enhancing the capabilities of Bobcat machinery. Innovations such as load-sensing hydraulics, which adjust the hydraulic flow based on demand, lead to increased fuel efficiency and extended operational life for the machinery. These technological improvements have been especially beneficial in a competitive market like China's, where minimizing costs and maximizing productivity are paramount.

The manufacturing process of hydraulic cylinders within China also deserves mention. As a region known for its robust industrial ecosystem, the production of hydraulic cylinders employs advanced manufacturing techniques and materials. This ensures that the cylinders meet the high standards expected by Bobcat and its customers. Local production not only reduces lead times but also contributes to economic growth by providing employment opportunities in manufacturing and related sectors.

In conclusion, hydraulic cylinders are the backbone of Bobcat’s equipment, facilitating essential movements and operations that define the brand's reliability. As Bobcat continues to strengthen its presence in China, the importance of high-quality hydraulic cylinders will only grow. By focusing on innovation, customization, and local manufacturing, Bobcat is well-positioned to meet the evolving needs of the Chinese market, thus, ensuring that its machines remain at the forefront of efficiency and performance in construction and agricultural tasks. Understanding the role of these hydraulic components is crucial for appreciating the overall functionality and effectiveness of Bobcat equipment in today’s competitive landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025