Aug . 30, 2024 17:33 Back to list

12 Volt Hydraulic Cylinder - Efficient Power Solutions for Your Hydraulic Applications

The Evolution of Hydraulic Cylinders in China A 2012 Perspective

In 2012, China witnessed significant advancements in hydraulic technology, particularly in the design and production of hydraulic cylinders

. Hydraulic cylinders play a vital role in heavy machinery, construction equipment, and various industrial applications, making their performance and reliability crucial to economic growth.At the heart of these advancements was a 2012 initiative to enhance the performance of hydraulic systems, focusing on improving efficiency, reliability, and load capacity. Chinese manufacturers began to adopt innovative engineering practices and materials, which allowed them to produce higher quality hydraulic cylinders that could withstand extreme conditions. The push for modernization in manufacturing processes led to the integration of advanced technologies such as computer-aided design (CAD) and simulation software, improving the precision of hydraulic cylinder components.

In the same year, several companies emerged as key players in the market, investing heavily in research and development. These investments aimed to cater to both domestic and international markets, positioning China as a significant competitor in the global hydraulic cylinder industry. Local manufacturers began to adhere to international standards, ensuring that their products met the stringent requirements of various sectors, including automotive, aerospace, and heavy machinery.

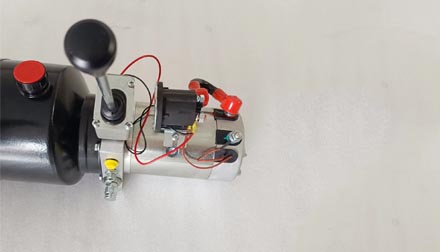

china 12 volt hydraulic cylinder

One of the notable features of hydraulic cylinders produced in 2012 was their increased energy efficiency. This was largely due to the implementation of innovative seal designs and hydraulic fluid formulations that reduced friction and leakage. As a result, the overall system efficiency improved, leading to lower operational costs for businesses relying on hydraulic systems.

Environmental considerations also gained traction in 2012, with manufacturers exploring eco-friendly materials for hydraulic cylinders. The shift towards sustainability not only addressed environmental concerns but also aligned with the growing global demand for greener technologies. This focus on eco-friendliness opened new avenues for companies to differentiate themselves in a competitive market.

Moreover, the rise of automation and smart technologies during this period prompted hydraulic cylinder manufacturers to explore the potential of integrating sensors and smart controls. These innovations facilitated real-time monitoring and control of hydraulic systems, enhancing operational safety and efficiency.

In conclusion, the evolution of hydraulic cylinders in China during 2012 marked a turning point in the industry. With a commitment to innovation, quality, and sustainability, Chinese manufacturers laid the groundwork for a future where hydraulic technology would continue to thrive, meeting the demands of a rapidly changing global market. As we look back at 2012, it is clear that this was a pivotal year that set the stage for China's prominence in the hydraulic cylinder industry.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025