Nov . 05, 2024 18:16 Back to list

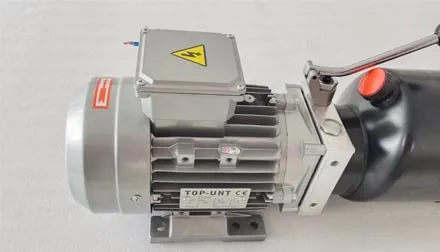

cascade hydraulic cylinder product

Understanding the Cascade Hydraulic Cylinder A Key Component in Modern Machinery

The cascade hydraulic cylinder is an integral component widely utilized in various industrial applications, ranging from automotive assembly lines to heavy construction equipment. Its unique design and functionality allow for efficient power transmission and precision control, making it essential for machinery that requires heavy lifting and precise movements.

What is a Cascade Hydraulic Cylinder?

A cascade hydraulic cylinder operates based on the principles of hydraulic power. It utilizes pressurized fluid to create motion, which is translated into mechanical force. This type of cylinder is commonly designed with multiple stages, or stages of extension, enhancing its capability to provide significant force in a compact form. It allows operators to achieve longer strokes without requiring excessively large cylinders, making it particularly useful in applications with space constraints.

Applications

In the construction industry, cascade hydraulic cylinders are utilized in excavators for digging and lifting operations. They enable the boom and arm of the excavator to operate smoothly, providing the necessary strength and control to handle heavy loads. In manufacturing, these cylinders are often found in automated systems, where precision is critical. They can effectively control the placement and manipulation of parts along assembly lines, contributing to increased efficiency and safety.

Benefits of Cascade Hydraulic Cylinders

1. Space Efficiency The multi-stage design allows for greater extension while maintaining a compact silhouette, making it ideal for environments where space is limited.

2. Power and Force These cylinders can generate substantial force, enabling them to lift and move heavy loads with relative ease. This capability is vital in heavy industry applications where safety and reliability are paramount.

cascade hydraulic cylinder product

4. Durability Typically constructed from high-quality materials, cascade hydraulic cylinders are built to withstand harsh operating conditions. Their robust construction ensures longevity and minimizes the need for frequent maintenance.

5. Versatility These hydraulic cylinders can be adapted for various applications, making them ideal for numerous industries, including agriculture, manufacturing, and construction.

Maintenance and Considerations

While cascade hydraulic cylinders are designed for durability, regular maintenance is crucial to ensure their longevity and performance. Operators should regularly inspect for signs of wear, leaks, and proper fluid levels. It is also essential to use the appropriate hydraulic fluid and keep the system clean to prevent contamination, which can significantly affect performance.

When selecting a cascade hydraulic cylinder for a specific application, it's important to consider factors such as load capacity, stroke length, and operating pressure. Each of these parameters plays a crucial role in the cylinder’s performance and suitability for a given task.

Conclusion

As industries continue to evolve, the demand for efficient and powerful hydraulic systems, including cascade hydraulic cylinders, will grow. Their ability to combine compact design with high performance makes them indispensable in modern machinery. Whether used in construction, manufacturing, or any field requiring precise movement of heavy objects, the cascade hydraulic cylinder stands out as a testament to engineering innovation and efficiency in the hydraulic realm. Understanding its functionality and applications is essential for anyone involved in operations relying on hydraulic systems, ensuring not only productivity but also the safe handling of materials in various working environments.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025