Nov . 23, 2024 09:40 Back to list

carbon fiber hydraulic cylinder factories

The Emergence of Carbon Fiber Hydraulic Cylinder Factories

In recent years, the manufacturing landscape has embraced innovative materials and technologies to enhance product performance and sustainability. One such advancement is the integration of carbon fiber into hydraulic cylinder production. The establishment of carbon fiber hydraulic cylinder factories marks a significant shift in the industry, promising not only improved functionality but also reduced environmental impact.

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it an ideal alternative to traditional materials like steel and aluminum in various applications, including hydraulic cylinders. These cylinders are crucial components in numerous industries, such as construction, aerospace, and automotive, where they facilitate powerful movements. By incorporating carbon fiber into their design, manufacturers can produce hydraulic cylinders that are lighter, more efficient, and resistant to corrosion.

The benefits of carbon fiber hydraulic cylinders are manifold. Firstly, the lightweight nature of carbon fiber allows for reduced operational stress on machinery, leading to enhanced efficiency and longevity. This is particularly beneficial in mobile applications where weight reduction can significantly improve fuel efficiency or battery life. Secondly, carbon fiber's resistance to environmental factors such as moisture, temperature fluctuations, and chemical exposure translates into a longer lifespan for hydraulic cylinders. Reduced maintenance costs and less frequent replacements further enhance the overall economic viability of carbon fiber products.

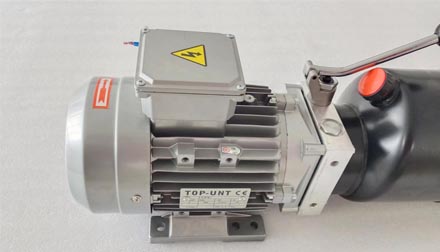

carbon fiber hydraulic cylinder factories

The establishment of dedicated carbon fiber hydraulic cylinder factories is a response to increasing market demand for these advanced materials. These factories utilize cutting-edge technology to streamline the production process, ensuring precision and quality in every cylinder manufactured. Automation and computer-aided design (CAD) systems play vital roles in optimizing the manufacturing workflow, allowing for greater scalability and customization based on specific customer needs.

As industries strive to adopt sustainable practices, carbon fiber hydraulic cylinders stand out as an eco-friendly option. The lightweight composition leads to efficient energy use, while the durability of carbon fiber reduces the need for frequent replacements, thus minimizing waste. Moreover, many carbon fiber production methods are evolving to utilize recycled materials and eco-friendly resins, further aligning with the global push towards sustainability.

However, the transition to carbon fiber hydraulic cylinders isn't without its challenges. The initial production cost can be higher compared to traditional materials, which may deter some manufacturers, especially smaller enterprises. Nevertheless, as technology advances and production methods become more efficient, the price of carbon fiber components is expected to decrease, making them more accessible to a broader range of industries.

In conclusion, the rise of carbon fiber hydraulic cylinder factories represents a pivotal moment in the manufacturing sector. The unique properties of carbon fiber significantly enhance the performance and lifespan of hydraulic cylinders while contributing to sustainability efforts. As the technology matures and costs become more competitive, it's likely that carbon fiber will become a standard material in hydraulic systems across various industries, leading to improved efficiency and environmental stewardship. The future of hydraulic applications looks promising with the innovative potential of carbon fiber at the forefront.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025